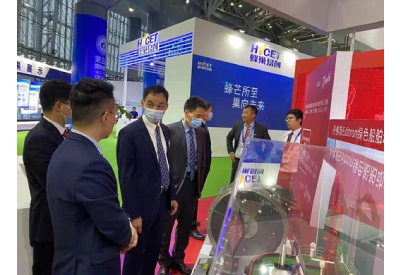

Danfoss Partners with Zhenjiang Shipyard to Accelerate the Electrification of China’s Marine Industry

November 22, 2021

- Danfoss China and Zhenjiang Shipyard’s partnership will further enhance the electrification portfolio of the biggest tugboat shipyard in the Greater China Region.

- Hybrid tugboats are optimized for green ports and directly impact the reduction of carbon emissions from China’s marine and shipping industries.

- Danfoss Power Solutions’ electrification division, Editron, will provide its hybrid marine system, one of the most compact and lightweight on the market, to boost efficiency and reduce carbon emissions.

Danfoss China has signed a cooperation agreement with leading Chinese shipyard Zhenjiang Shipyard to quicken the rate of electrification in the Chinese marine industry

The agreement between Danfoss China and Zhenjiang Shipyard is directly aligned with China’s strategy to boost green shipping and will see the two companies partner to further enhance Zhenjiang Shipyard’s hybrid tugboats, the star vessel of the business’ portfolio. With an average of 30 tugboats delivered annually, Zhenjiang Shipyard is the biggest tugboat shipyard in China.

China has seven of the world’s 10 largest container ports and handles nearly one-third of all global seaborne containerized trade. To reduce emissions from its marine and shipping industries, the country is focusing on developing green ports. Hybrid tugboats are a perfect vessel for green ports, as they perform as well as diesel-powered equivalents while drastically reducing emissions.

As part of the agreement, Danfoss will provide Zhenjiang Shipyard with its state-of-art electric propulsion products. This includes the company’s EDITRON hybrid marine system comprising a large motor product and DC-link grid system. Danfoss’ Editron system is one of the most compact and lightweight on the market and will boost the efficiency of tugboats while drastically reducing carbon emissions. The company will also work closely with the shipyard to optimize the design of the vessels and minimize production management costs.

Arthur Xu, President of Danfoss China, commented:

“While the market for hybrid tugboats in China is still in its infancy, it has strong potential as the country is looking to reduce emissions by increasing green shipping. We’re delighted to be working with one of the Chinese leaders in the industry and look forward to expanding the company’s hybrid tugboats portfolio.”

Wang Weilin, Deputy General Manager at Zhenjiang Shipyard, added:

“Hybrid and fully electric ships are urgently needed to achieve global carbon neutrality. Our hybrid tugboats represent an optimal solution for green ports, which is why we’re focusing on enhancing our portfolio to maximize their efficiency. Danfoss’ electrification division, Editron, is renowned in this field, with excellent products and a fantastic reputation. We’re delighted to cooperate with them on the platform supported by Zhenjiang national High-Tech Zon to boost the green credentials of the Chinese marine industry and contribute to global energy savings and emissions reduction.”

Chao Wang, Head of Sales, Editron, China, Danfoss, stated:

“With more than 10 vessels built with Editron solutions since 2019, Danfoss Editron has been one of the market leaders in China by providing the latest technology in marine propulsion solutions. With Zhenjiang shipyard, we will expand into vessel types such as tugboats, where Danfoss’ Editron’s solution provides one of the smallest footprints and enables electric propulsion in a vessel that is compact and yet requires high power.”

To watch a video about Danfoss’ electric drivetrain system, Editron, click here

For more information on Danfoss, click here