Beckhoff Plans Virtual US Debut of XPlanar, XTS Updates During Pack Expo Connects

October 5, 2020

Empowering new breakthroughs in packaging machine design, Beckhoff Automation will showcase innovative mechatronics and PC-based automation technologies during Pack Expo Connects. Flying motion with XPlanar, a stainless steel version of the eXtended Transport System (XTS) and other hardware, software and networking innovations will be on display in virtual booth #213 or www.pe.show/213. Beckhoff USA Product Managers will host multiple educational sessions to discuss core packaging technology topics during the weeklong digital event from November 9 – 13, 2020.

Elevate packaging machine concepts with XPlanar

The eXtended Planar Motor system, XPlanar, will demonstrate flying motion during its debut trade show appearance in North America. The system uses planar motor tiles as a base to levitate passive movers at speeds of 4 m/s and acceleration up to 20 m/s². Path planning and collision avoidance software produce extremely efficient and maintenance-free motion control for complex packaging, inspection and material handling applications.

Anti-sloshing functionality based in TwinCAT 3 software optimizes XPlanar’s transport capabilities in applications involving liquids, such as filling of beverages, cosmetics and other goods. Wear-free movement and the ability to cover planar motor tiles with stainless steel, glass or another surface ensure XPlanar is a sanitary, wash-down-capable solution. With these capabilities, the innovative system enables ultimate flexibility and allows machines to achieve lot size 1 production.

Next-step linear transport: XTS Hygienic and Track Management

XTS, the paradigm-shifting linear transport technology from Beckhoff, returns to Pack Expo with new hardware and software expansions. XTS Hygienic, a stainless steel, IP69K version, is ideal for wash-down production environments in packaging, pharma, food and beverage. In addition, new Track Management functionality allows individual movers to transfer between multiple XTS systems, enabling further customization, quality inspection, automatic defect ejection and more. These features, along with the system’s high speeds, dynamics, small footprint, instant recipe changeovers and real-time integration with robotics, further revolutionize possibilities in packaging.

Complete automation platform solves today’s packaging challenges

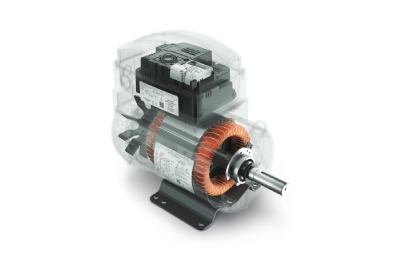

Beckhoff drive technology updates at Pack Expo Connects will include new AL80xx Linear Servomotors, additional capabilities from the space-saving, high-performance AX8000 servo system and the U.S. launch of the AA2518 Tubular Motor. With high dynamics and precision, the AA2518 replaces mechanical components, such as spindles, while delivering a maximum force of 1,050 N and acceleration rates of 8 m/s.

Among the other PC-based automation, motion control, IoT and EtherCAT solutions suited to packaging will be TwinCAT Vision and TwinSAFE functional safety. TwinCAT Vision offers comprehensive, real-time image processing to reduce latency and engineering effort using standard PLC languages and GigE cameras. Using the proven EtherCAT industrial Ethernet system, Beckhoff offers a scalable, modular and fully integrated safety system in TwinSAFE, which expands design flexibility, diagnostics and data insights for packaging machines.

“Beckhoff views Pack Expo Connects as an important opportunity for packaging machine builders and CPG manufacturers to connect virtually and continue learning about key technology advances during this unprecedented time,” said Mark Ruberg, Packaging Industry Manager for Beckhoff Automation LLC. “With the market facing new challenges constantly, innovative technologies like XPlanar and XTS Hygienic provide opportunities to future-proof packaging machine designs and enable lot size 1 production. These build on the proven foundation of PC-based automation from Beckhoff, TwinCAT software and EtherCAT, and together they empower new IoT and Industrie 4.0 concepts for packaging.”

For more information, visit www.beckhoffautomation.com.