Unique forms of motion derived from nature: Projects from the Bionic Learning Network of Festo

December 7, 2018

Over ten years ago Festo initiated the Bionic Learning Network. In cooperation with students, renowned universities, institutes and development companies, Festo sponsors projects, testbeds and technology platforms – the Motto: Inspired by nature. The objective is to benefit from bionics as a source of inspiration for new technologies and to realise these in industrial automation. The network is closely linked with the processes of innovation within the company.

The so called Future Concepts of the Bionic Learning Network serve as development platforms that combine a wide diversity of technologies and components – from manufacturing concepts via series products, up to software and control or regulation technology. Continuous optimisation of the various technologies provides Festo with complex insights and approaches to developing and optimising new products and applications together with customers and partners.

AquaJellies – autonomous behaviour in a collective

Like their natural model, the AquaJellies glide elegantly and seemingly effortlessly through the water. This is ensured by their adaptive tentacles, which are controlled by an electric drive in their body. The integrated communication and sensor technology plus the real-time diagnostics enable coordinated, collective behaviour of several jellyfish, even in a limited space. An app can be used to individually record and track the current condition of each AquaJelly. With the AquaJellies 2.0, Festo is visualising potential and ideas of how efficient systems in the field of water technology may look in the future. Process monitoring and condition monitoring are important topics in all equipment used in the process industry and hence also in the water technology sector. The task of self-organisation can already be found in wastewater technology today, for example when it comes to channelling collected rainwater from several decentralised rain overflow basins into a central sewage treatment plant. At the same time, condition monitoring allows efficient operations management, servicing and maintenance.

Festo presented the AquaJellies for the first time in 2008. This year the Bionic Learning Network has once again presented new projects. The natural models were the flic-flac spider and the flying fox.

The BionicWheelBot: Unique forms of locomotion of the flic-flac spider

The biological model for the BionicWheelBot is the flic-flac spider (Cebrennus rechenbergi), which lives in the Erg Chebbi desert on the edge of the Sahara. Professor Ingo Rechenberg, a bionics professor at the TU Berlin, discovered it there in 2008. The flic-flac spide r can walk like other spiders; however, it can also move with a combination of somersaulting and rolling on the ground. It is therefore ideally adapted to its surroundings: on even ground, it is twice as fast in so-called rolling mode than when walking. Since the spider’s discovery, Professor Rechenberg has been working on transferring its movement patterns to technological applications. On the basis of these extensive studies, Rechenberg and his team first constructed a number of prototypes for the BionicWheelBot. He has now further developed the kinematics and drive concept of the artificial spider together with Festo as part of the Bionic Learning Network.

r can walk like other spiders; however, it can also move with a combination of somersaulting and rolling on the ground. It is therefore ideally adapted to its surroundings: on even ground, it is twice as fast in so-called rolling mode than when walking. Since the spider’s discovery, Professor Rechenberg has been working on transferring its movement patterns to technological applications. On the basis of these extensive studies, Rechenberg and his team first constructed a number of prototypes for the BionicWheelBot. He has now further developed the kinematics and drive concept of the artificial spider together with Festo as part of the Bionic Learning Network.

The BionicWheelBot: transition from walking to rolling mode

Just like a natural spider, the BionicWheelBot propels itself with a tripod gait, whereby it uses six of its eight legs to walk. In order to start rolling, the BionicWheelBot bends three legs on each side of its body to make a wheel. The two legs that are folded up during walking are then extended, push the rolled-up spider off the ground, and continuously push it forward whilst rolling. This prevents the Bionic WheelBot from grinding to a halt and ensures that it can keep moving forward even on rough terrain.

WheelBot from grinding to a halt and ensures that it can keep moving forward even on rough terrain.

In rolling mode, the BionicWheelBot performs a somersault with its whole body, just like the real flic-flac spider. Thanks to its integrated inertial sensor, it always knows what position it is in and when it has to push off again. It, too, is therefore much faster when rolling than walking, and it can even overcome uphill inclines of up to five per cent.

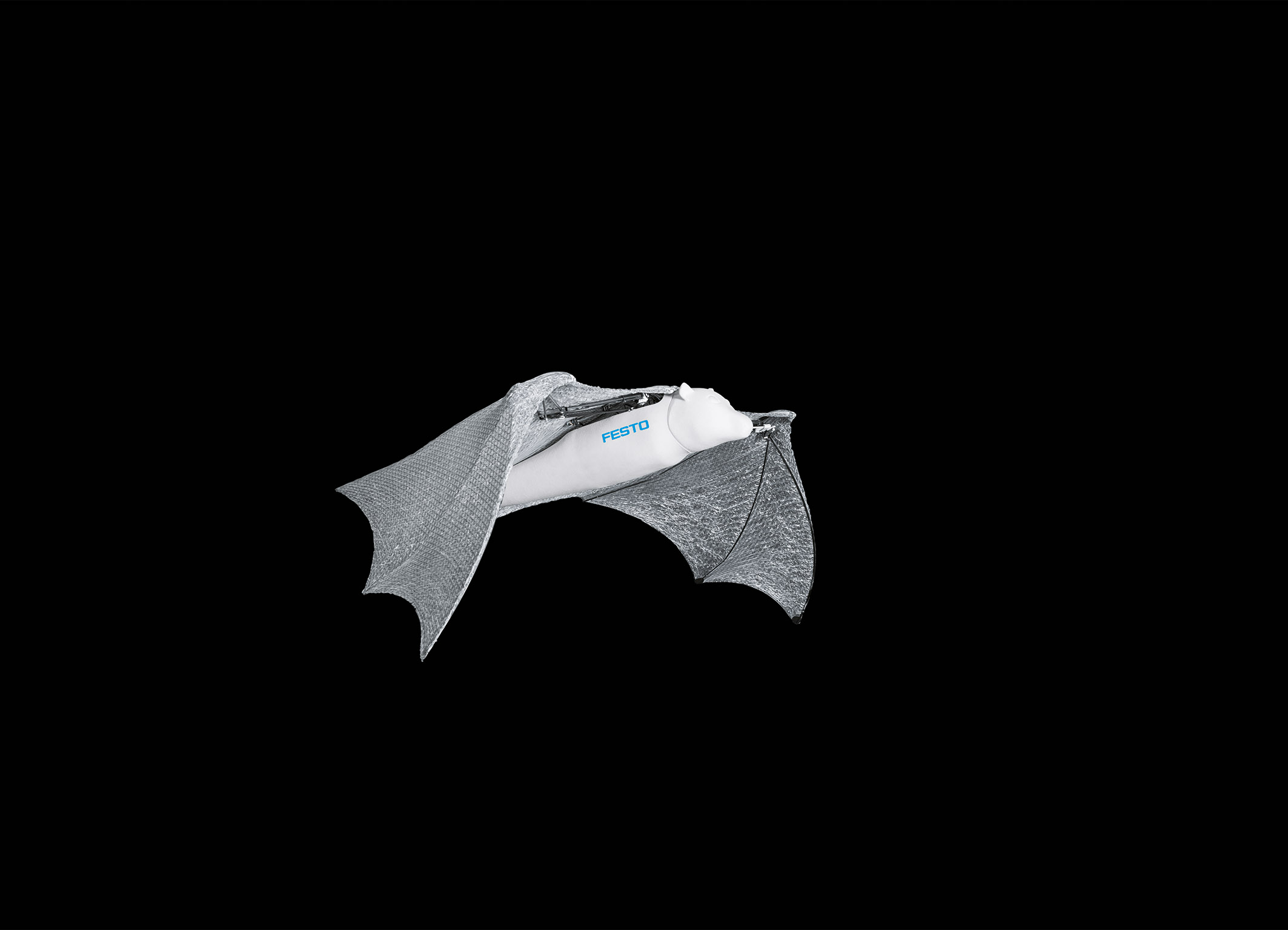

BionicFlyingFox – ideal flight path thanks to machine learning

To emulate the natural flying fox as closely as possible, the wing kinematics of the BionicFlyingFox are also divided into primaries and secondaries; all the joints lie in the same plane. The wings are covered with an elastic membrane, which extends down to the feet. This flying membrane is wafer-thin and ultralight, but also robust.

Motion tracking system for semi-autonomous flight

To enable the BionicFlyingFox to move semi-autonomously within a defined space, it communicates with a so-called motion tracking system. The installation with two infrared cameras constantly records its position. The cameras, which are mounted to a pan-tilt unit, can be rotated and inclined in such a way as to track the entire flight of the BionicFlyingFox from the ground. At the same time, the motion tracking system plans the flight paths and issues the required control commands. Starting and landing are performed by the human operator; the autopilot takes over in flight.

rotated and inclined in such a way as to track the entire flight of the BionicFlyingFox from the ground. At the same time, the motion tracking system plans the flight paths and issues the required control commands. Starting and landing are performed by the human operator; the autopilot takes over in flight.

Machine learning for the ideal flight path

The images from the cameras are conveyed to a central master computer, which evaluates the data and externally coordinates the flight like an air traffic controller. Pre-programmed flight routes stored on the computer specify the path taken by the BionicFlyingFox in performing its manoeuvres. The wing movements required to ideally implement the intended movement sequences are calculated by the artificial flying fox itself with the help of its on-board electronics and its complex behaviour patterns. The flying fox receives the necessary control algorithms from the master computer, where they are automatically learnt and constantly improved. The BionicFlyingFox is thus able to optimise its behaviour during flight and thereby follow the specified courses more precisely with each circuit flown.

Innovative flying membrane for various different applications

The innovative flying membrane was specially developed by the bionics team for the BionicFlyingFox. It consists of two airtight foils and a woven elastane fabric, which are welded together at approximately 45,000 points. The fabric’s honeycomb structure prevents small cracks in the flying membrane from increasing in size. The BionicFlyingFox can thus continue flying even if the fabric sustains minor damage. Due to its elasticity, the flying membrane stays almost uncreased even when the wings are retracted. Since the foil is not only elastic, but also airtight and lightweight, it could also potentially be used in other flying objects or for clothing design and in the field of architecture.

For further information: www.festo.com/bionics

Video download: BionicWheelBot and BionicFlyingFox

http://www.presslive.de/bionicwheelbot

http://www.presslive.de/bionicflyingfox