Rittal at SPS IPC Drives 2018: Solutions for control and switchgear engineering 4.0

November 30, 2018

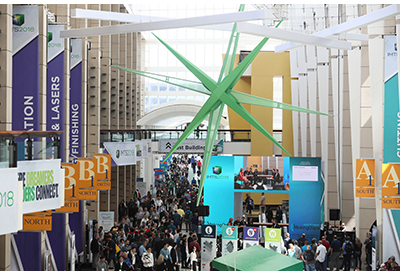

The solution provider for the control and switchgear engineering value chain: this is how Rittal presented itself at the SPS IPC Drives automation trade fair in Nuremberg from 27 to 29 November. The highlight is the presentation of the new VX25 large enclosure system under the motto of “System Perfection”: the first enclosure system that has been fully developed to meet the demands for increased productivity and Industry 4.0. Together with Eplan, Rittal also promises a significant increase in productivity through integrated solutions with software tools and data, as well as the new Wire Terminal for fully automatic wiring pre-assembly.

“Increasingly, our customers in control and switchgear engineering are expecting complete solutions to improve the overall efficiency of their product development and production processes,” says Uwe Scharf, Executive Vice President at Rittal. “At SPS IPC Drives 2018, we will prove that Rittal has consistently thought its way beyond individual products and into the value chain of control and switchgear engineering. These integrated solutions offer tangible benefits such as high cost-effectiveness, speed and innovation,” the head of the Industry Business Unit added.

The best example is the new VX25 large enclosure system. Intensive dialogue with customers was crucial in developing it. No less than 150 specific requirements for the enclosure of the future became apparent following a large-scale, scientifically based usability study of control and switchgear engineers in Germany, the USA and China. Rittal also consulted the customer advisory council and incorporated its feedback into the development process.

The VX25: systematically developed

The result of the development is being presented by Rittal at SPS IPC Drives. The VX25 has succeeded in preserving all the important and established product features of the previous, worldwide TS 8 standard, as well as integrating a multitude of functions. Never before has an enclosure system been developed in such a consistent and systematic way in order to ensure maximum customer benefit. The new Rittal large enclosure matches the way the control and switchgear manufacturers think and work, both in terms of functions and processes. Key features of the VX25 include reduced complexity, time savings and secure assembly, as well as the maximum quality and continuity of data.

VX25: experience the practical benefits

Visitors can familiarise themselves with the new enclosure system at a highlight area at the centre of the Rittal booth, with more than 1,120-m² in area. The manufacturer is showing details of the new technical features on a number of islands. Practical workshops will be held to make the advantages of the VX25 tangible. For example, the assembly of doors and panels, the installation of punched sections, the retrofitting of the 180° hinges and comfort handles, as well as the baying of enclosures will be demonstrated.

The VX25: suitable for extreme conditions and currents up to 6,300 A

Rittal is also showing that the new large enclosure can also be used where demands are extremely high. All the benefits of the VX25 are also available in stainless steel and NEMA 4X versions. The manufacturer is thus making its new development fit for customers who demand the highest levels of protection from corrosion and for acceptance in the North American market. The features include increased protection from dust and rain, as well as splashes and jets of water.

Rittal will also be presenting the VX25 Ri4Power, a further development of the large enclosure for the configuration of low-voltage switchgear in accordance with IEC 61439-2. This features a new system configuration including a new busbar system, by means of which the power range can be increased to up to 6300 A while, at the same time, the use of copper is reduced.

Integrated value chain: The “Wiring” showcase feature

Using the example of enclosure wiring, Rittal and Eplan are showing how the product manufacturing process in control and switchgear engineering can be improved through digitization, standardisation and automation. The route from the circuit diagram to planning the wiring in 3D, to the automatic production of the individual wires and finally to installation and testing is clearly presented. The companies will be presenting integrated solutions all along the value chain: from the provision of digital article data and product configurators to the engineering and work preparation process in which the enclosure’s digital twin is created, right through to digitally connected production.

The highlight is the presentation of the Wire Terminal WT from Rittal Automation Systems, a new automatic wire pre-assembly machine for the fully automatic wiring pre-assembly of different wire cross-sections. On top of this, Rittal and Eplan will be presenting their Value Chain Consulting service for products and solutions.

Further product highlights

Rittal will also be presenting numerous other product highlights at the SPS IPC Drives event: The company is presenting a height-adjustable support section for ergonomic machine operation with which operator terminals can be flexibly and easily positioned on machines with the aid of support arm systems. New components for the RiLine Compact power distribution system such as motor control units, 125-A connection adaptors and single-pole component adapters will also be presented. Trade visitors will also be able to find out about the new enclosure and housing solutions for Commeo and Tesvolt, providers of energy storage devices, for developing infrastructure solutions for energy storage systems.

In the enclosure climate control segment, Rittal is expanding its energy-efficient Blue e+ cooling unit series by introducing the new 1.6 kW power class, a stainless steel version and, for the first time, a roof-mounted version with 1.3 kW. Another special feature is the VX25 Blue e+ integration solution: a pre-installed plug & play solution consisting of a VX25 enclosure and a highly efficient Blue e+ cooling module. In addition, cooling solutions for process cooling will be presented. These include the new Blue e+ Chillers in the 2.5, 4 and 5.5 kW output classes and 11– 25 kW Blue e Chillers. With the new IoT interface, Rittal also enables Blue e+ units to network with Blue e+ cooling units and Blue e+ chillers with customer-specific monitoring, energy management and/or superordinate systems via OPC-UA, Profinet, SNMP, Modbus TCP and CANopen, paving the way for new applications such as predictive maintenance and data analytics.

Secure edge data centres for Industry 4.0

The new Secure Edge Data Center is yet another innovation in the IT segment. This turnkey data centre solution, developed by Rittal along with global partners ABB and HPE, is designed to operate in tough industrial environments. With the aid of secure edge data centres, companies can now access and respond to critical data in real time, capture it within a short latency period and, at the same time, secure the connection to a cloud.