Mass production was yesterday

August 6, 2019

EMO: SuperTrak brings batch size one to the metal industry

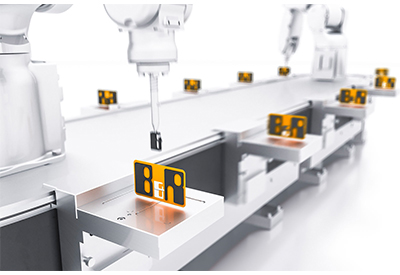

The metal industry is not immune to the global trend away from bulk annual orders toward small-batch customer orders with short lead times. To handle this type of individualized production in batch sizes as small as one, manufacturing systems must become much more flexible. B&R’s booth at EMO (Hall 9, Booth F50) will showcase track-based transport technology, whose independently controlled shuttles and rapid changeover times enable flexible, customer-centered manufacturing.

Track-based flexibility

Large annual bulk orders are giving way to smaller orders with shorter lead times and frequently changing requirements. Meeting these demands requires manufacturing systems that can adapt to these changes quickly and easily. AT EMO, B&R will showcase its SuperTrak transport system, which can be scaled in one-meter increments. The independently controlled shuttles give machine designers all the flexibility they need. A demo system featuring ABB robots highlights how seamlessly other subsystems can interact with the track system and perform additional production tasks.

Efficiency and profitability

Mass customization centers around an ability to produce small batches cost-effectively. Users of track technology benefit from high transport speeds and short changeover times that make manufacturing profitable down to batch size one.