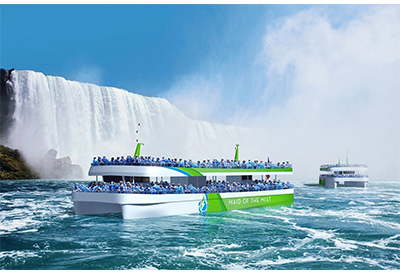

ABB powers tourists to the Niagara Falls with first US built all-electric vessels

May 9, 2019

Visitors to the iconic Niagara Falls will soon be able to experience one of the US’s top landmarks emission-free. Two new Maid of the Mist passenger vessels will be powered entirely by high-capacity battery packs, becoming the first all-electric vessels ever built in the US.

The new vessels will benefit from ABB’s zero-emission technology when they start operating later this year, allowing guests to experience Niagara Falls undisturbed by engine noise, vibration or exhaust fumes from a conventional diesel engine.

Maid of the Mist, one of North America’s oldest tourist attractions, operates from April through to the first week of November, with boats departing for the base of Niagara Falls every 30 minutes, with an estimated 1.6 million guests on board annually.

“We are thrilled to be the US’s first vessel owner to add all-electric ferries to our fleet,” said Christopher M. Glynn, president of Maid of the Mist Corp. “We have chosen ABB to support us in our journey towards more sustainable operation based on their unparalleled experience in marine system integration, as well as efficient and innovative technologies for sustainable transportation.”

“Maid of the Mist’s decisive move towards e-mobility signals a new era in the future of transportation and complements ABB’s commitment to power the world without consuming the earth,” said Peter Terwiesch, President of the Industrial Automation business at ABB, which offers solutions for a wide range of industries, including marine. “Reducing emissions at Niagara Falls is not only important for the natural landmark, but also proves that the technologies enabling sustainable mobility are already available today.”

Each of the vessels will be powered by a pair of battery packs with a total capacity of 316 kWh, split evenly between two catamaran hulls. Having two fully independent power systems on board will increase the resilience of operations by creating a redundancy.

The vessels will charge between every trip while passengers disembark and board. Shoreside charging will only take seven minutes, allowing the batteries to power the electric propulsion motors capable of a total 400 kW (563 HP) output. The power setup will be controlled by ABB’s integrated Power and Energy Management System (PEMS), which will optimize the energy use on board.

The batteries will be charged using hydropower – the largest single renewable energy source for electricity generation in the US, which accounts for 7 percent of the country’s total utility-scale electricity generation. The use of locally produced renewable power will make the energy cycle for the operation of the new Maid of the Mist vessels entirely emission-free.

Sustainable transportation has a crucial role in the fight against climate change, with shipping accounting for 2 to 3 percent of the world’s total greenhouse gas emissions. The International Maritime Organization, a United Nations agency responsible for regulating shipping, has set a global target to cut annual emissions by at least 50 percent by 2050 from 2008 levels.

In addition to integrating the ship-to-shore battery charging connection, ABB will supply the Maid of the Mist newbuilding project with switchboards, drives and the integrated control system, as well as the ABB Ability™ Marine Remote Diagnostic System for remote equipment monitoring and predictive maintenance. ABB Ability is ABB’s leading offering of digital solutions and services.

For more information, visit HERE.

This expansion marks an important milestone for their business as they continue to grow and serve their customers with even more proximity and commitment. They look forward to welcoming…

This expansion marks an important milestone for their business as they continue to grow and serve their customers with even more proximity and commitment. They look forward to welcoming…