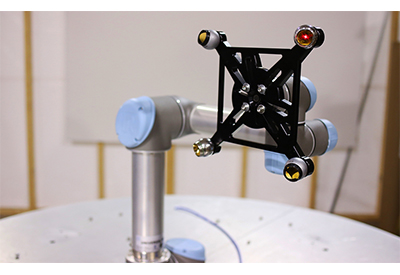

Printing With Precision – Improving Existing High-Speed Equipment

The Scenario: A high-speed printing company had partially completed an upgrade to their equipment. The printing machine used two alternating print heads to produce units at a rate of more than 11/s. Due to the nature of the product, speed, accuracy, and repeatability were extremely important. The process needed to be consistent as any defect would impact production further down the line.