Stay Resilient Against Resonance with AC Drives Adaptive Tuning

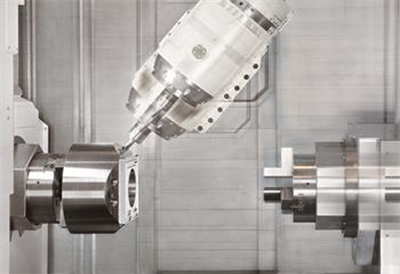

It can be a scary moment on the plant floor: A machine starts shrieking and shaking so violently, you think it might break. This incident can result from mechanical resonances caused by a load attached to a motor. Many design factors attribute to the resonances such as physical size, material selection, and instillation procedures. And while workers can usually make a control adjustment to resume production, resonance issues have lasting consequences on your machines and your business.