6 Reasons for KEB PROFINET Servo Drives

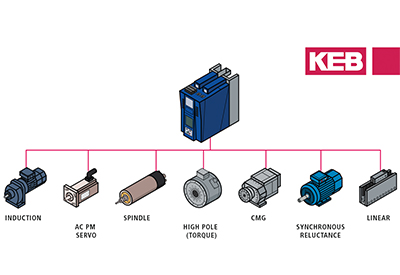

Since KEB is a German-based company, they have a long history connecting their PROFIBUS and PROFINET drive products with Siemens PLCs. KEB’s PROFINET offering now extends to the next generation S6 Servo Drive and F6 VFD product lines. KEB’s customers choose KEB PROFINET servo drives for a number of reasons. Customer feedback shows they value KEB’s direct support from engineers, good value (price vs. performance), and a lot of technical features built into the KEB product as standard.