Evolution 4.0: Enabling the Right Moves

Speed and service are key to exceeding customer expectations, requiring more integrated practices, accessible intelligence and automated operations than ever before.

Speed and service are key to exceeding customer expectations, requiring more integrated practices, accessible intelligence and automated operations than ever before.

In the absence of a predictive maintenance strategy, manufacturers must take care of their equipment with regularly scheduled preventive maintenance. According to Plant Engineering, manufacturers spend an average of 19 hours per week maintaining their equipment.

ABB has recently been awarded a major turnkey contract by Statkraft, Europe’s largest generator of renewable energy, to design, manufacture and install two high-inertia synchronous condenser systems for the Lister Drive Greener Grid project at Liverpool in Northwest England.

Traditionally, many industrial companies have relied on their service providers to help keep their operations running profitably, safely, and reliably. The need for this relationship remains, but the challenge is how to perform service and maintenance duties amid current and future lockdowns, travel restrictions, and social distancing.

Some ten billion bearings are manufactured each year and, given the harsh conditions to which they are often subjected, they are incredibly reliable. Indeed, approximately 90% of these bearings outlive the equipment to which they are fitted.

Sulzer has used a fiber-optic sensing system from SKF to verify the design of a new centrifugal process pump. The sensing system measures loads directly in the bearing, which gives a deeper insight into a pump’s actual operating conditions.

As factory automation evolves with Industry 4.0, advanced technology continues to introduce more accurate and innovative features, many of which are used to protect personnel and equipment.

75 years of the HARTING Technology Group: During this period there have been many innovative developments and solutions in the automation market. Even though HARTING has been working in partnership with SEW-EURODRIVE for less than 75 years, there have been numerous successful joint projects over the past few decades.

LAPP’s test facility for cables is CSA certified under the CSA Supervised Manufacturer’s Testing for Certification (SMTC) Program. Although UL has a Canadian equivalent, cUL, the CSA mark is more broadly accepted by designers, contractors and machine builders in Canada and other international regions.

As the world prepares to immunize against COVID-19 in the coming weeks and months, there will be real logistical challenges involving the storage, transportation, and distribution of the vaccine under temperature-controlled conditions throughout the entire cold chain.

Process Instrumentation & Controls’ manufacturer, BECK, understands that your business cannot always wait until it’s convenient for your actuator supplier to ship. That’s why when urgent situations arise, Beck can respond by building and shipping most actuator configurations within four hours.

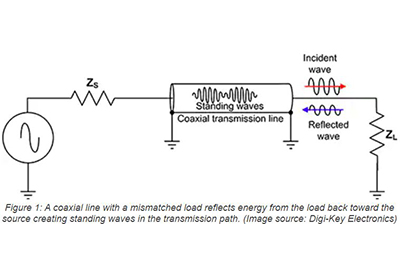

Users of electronic instrumentation equipment that involves the transmission or reception of high-frequency electrical signals are familiar with coaxial connections as they are used prolifically. So much so that such connection types can be taken somewhat for granted—until it comes time to connect multiple instruments together or extend coaxial cables.

Rittal and EPLAN are starting the New Year by offering a chance to make their customers’ value-creating processes faster, more economical and more exact, with a value-filled event entitled “Panel building. Made smarter.” This is a great opportunity to attend this event live from anywhere around the World.

ABB has recently been awarded a contract by Hitachi Rail (Hitachi Rail STS USA, Inc.) to provide traction power equipment for the Hurontario Light Rail Transit (HuLRT) project in Toronto, Canada. Among its roles, Hitachi leads the Systems and Revenue Vehicle components of the project. The contract value of the Hurontario LRT is $4.6 billion. The Hurontario LRT is expected to open in late 2024.

Conversations about automation technology and design often focus on one thing – the technology itself. We think of the high-tech robots, the automated conveyors, or the precision welding machines that make it possible for factories to operate more efficiently, productively, and safely.

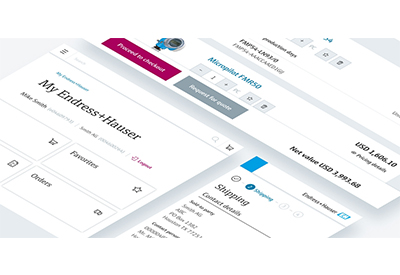

More and more measurement instruments are being ordered online from Endress+Hauser. In the first five months of 2020, incoming orders via endress.com nearly doubled. With the introduction of the new FLEX product segmentation structure, integration of the global E-direct portal into the website and further optimization of the e-commerce area on endress.com.