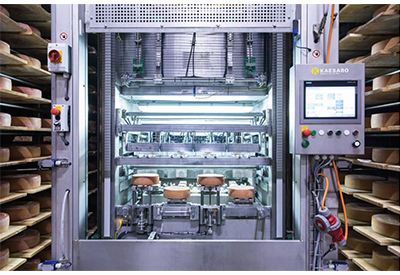

F&B Pro: A Fine Solution for Cheese Production

Maturation is an important process in cheese production. The longer a cheese matures, the spicier it becomes, it develops its unmistakable aroma. However, the ripening process involves a lot of work. The loaves must be regularly brushed and brushed with brine. In the past, this was done almost everywhere by hand and required considerable effort.