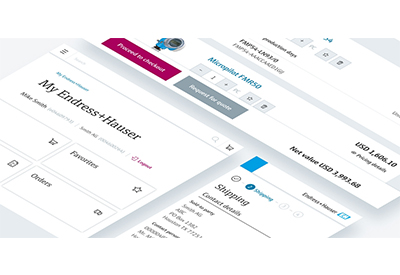

Endress+Hauser: One-Stop Shopping

More and more measurement instruments are being ordered online from Endress+Hauser. In the first five months of 2020, incoming orders via endress.com nearly doubled. With the introduction of the new FLEX product segmentation structure, integration of the global E-direct portal into the website and further optimization of the e-commerce area on endress.com.