Applying Energy-Efficient Solutions to Electric Motors Is One of The Biggest Tickets to Save Energy” – Podcast with ABB’s Adrian Guggisberg

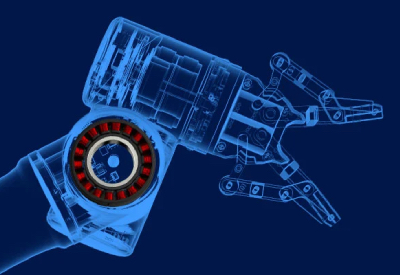

Electric motors are ubiquitous, powering heavy industrial machineries to everyday household appliances. Nearly half of the world’s electricity is used in powering electric motors, many of which are running with poor efficiency. In the latest episode of ABB Decoded podcast, Adrian Guggisberg, President of ABB’s Motion Services division, discusses how a significant amount of energy can be saved by applying digital technologies to the installed base.