ABB Strengthens Roller Table Motor Offering for Global Steel Industry

January 29, 2025

- ABB’s IEC Low voltage Roller table motors are now available at pace in response to increasing demand

- The motors, designed specifically for the steel industry’s rolling mills, have up to 20-year lifespan and have been shown to slash operating costs at mills around the world

- The global steel industry is facing rising costs and tighter environmental regulations, making operational efficiency key to staying competitive

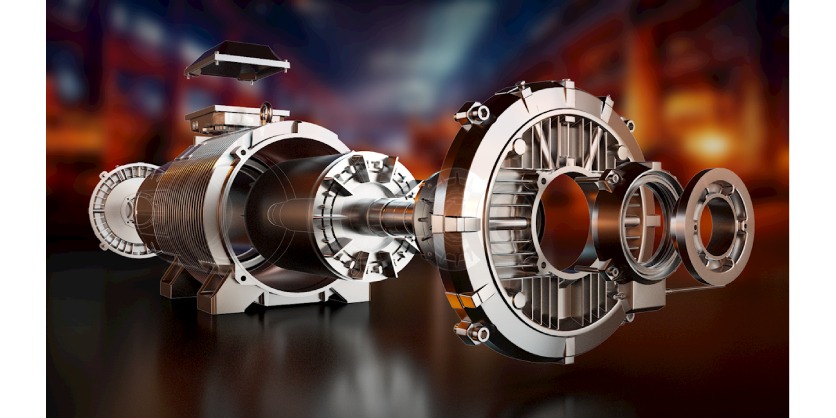

ABB has strengthened its Roller table motor offering, increasing availability in response to growing demand. The motors, designed specifically for the hot and corrosive environment of steel mills, are paired with ABB variable speed drives (VSD), allowing for intense and dynamic workloads while minimizing downtime and operational costs.

ABB’s Roller table motors have a long lifespan thanks to the product’s shock-proof, temperature-resistant shell that repels both dust and moisture, as well as ABB’s world-leading quality and reliability performance testing.

Peter-Stefan Tampsi, Segment Manager at ABB IEC Low voltage motors, says, “The steel industry operates under intense and very demanding conditions, both in terms of the manufacturing process and the market. The robustness of the Roller table motor perfectly paired with ABB VSD can play a major role in competitiveness and profitability.”

ABB’s Roller table motors are purpose-built to meet the steel industry’s need for increased efficiency and reliability. The product’s dimensions, arrangements, and power ratings are fully customisable and can be installed with minimal disruption. Even at older mills which haven’t had an infrastructure upgrade in decades, installation is seamless.

Peter-Stefan Tampsi continues, “A joined-up approach to motor and VSD selection is key to streamlining the wider upgrade of the global steel industry. More than ever, we’re aiming to be a one-stop shop for the industry, and our Roller table motors are now available at pace.”

ABB itself has over 30 years of experience providing Roller table motors to the steel industry and operates in more than 100 countries around the world, giving the company unique insight and experience into the common and unique challenges in each region.

More Information

Click here for more information about ABB’s IEC Low voltage Roller table motors.

Related Story

ABB to Support New H2 Green Steel Plant in Sweden with Around 1,200 Energy-Efficient Drives

SMS group, a specialist in plant construction and mechanical engineering for the metals industry, has selected ABB’s latest generation of drives to provide process technology for H2 Green Steel plant in Boden, Sweden. Globally, the steel industry is responsible for an estimated 8 percent of the world’s energy demand and generates between 7 percent to 9 percent of CO₂ emissions – most of which are from burning fossil fuels, according to the recent International Energy Agency (IEA) Iron and Steel Technology Roadmap. The project is currently in its first phase and will begin production at the end of 2025. It uses hydrogen in the furnaces rather than fossil fuels, resulting in steel with 95 percent lower CO2 emissions than conventional methods.