ABB Baldor-Reliance Food Safe SP5+ Motor Delivers the Highest Levels of Efficiency and Protection to the Food & Beverage Industry

January 23, 2025

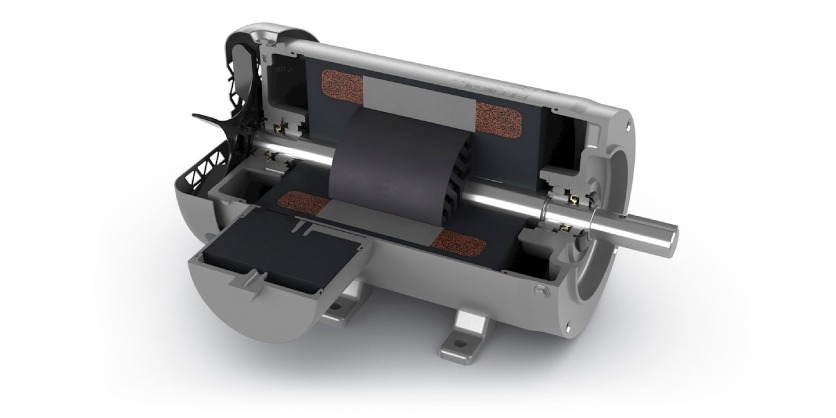

ABB, a global leader in food processing motor and drive technologies, has developed its next generation of energy-efficient motor solutions for the food and beverage industry. The Baldor-Reliance® Food Safe SP5+ is the world’s first IP69 ultra-premium efficient motor. Engineered for seamless inverter duty operation with advanced bearing protection, it utilizes cutting-edge rotor technology to achieve peak efficiency, reducing energy costs and supporting sustainability goals.

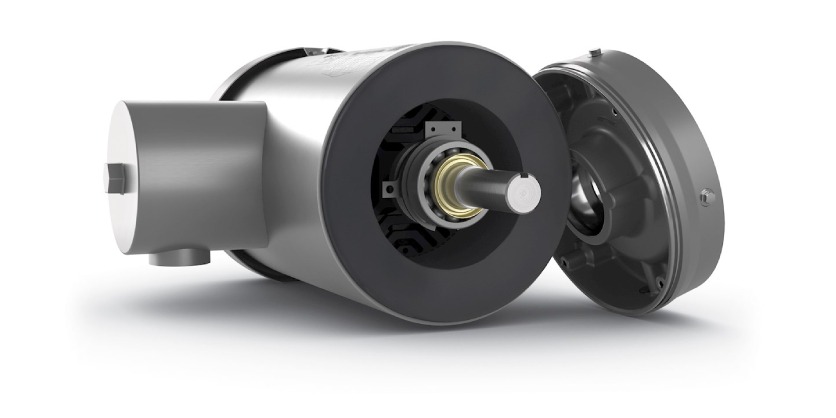

Designed to meet the highest standards for food processing, all ABB Food Safe motors are easy to clean and maintain, offering durability and reliability in demanding environments. SP5+ achieves an IE5 efficiency level* and is manufactured for high performance in NSF-identified food zones (zone 1), which includes areas that come into direct contact with food, as well as surfaces from where food may drip, drain or splash back onto surfaces that are in direct contact with food. SP5+, like all Baldor-Reliance Food Safe motors, can be effectively cleaned to a hygienic level to ensure uncompromised food safety. With local manufacturing and comprehensive service support, Food Safe SP5+ ensures exceptional performance and longevity in harsh food processing environments.

With the launch of the Food Safe SP5+, ABB continues to set the standard for innovation in motor-driven systems. The entire Food Safe SP5+ portfolio offers:

- Unrivaled energy efficiency: Advanced rotor technology optimizes performance, lowering energy consumption and helping facilities meet or exceed current and future efficiency standards. Food Safe SP5+, with the use of a required variable speed drive, meets or exceeds the IE5 efficiency level.*

- Exceptional hygiene standards: Designed for harsh washdown environments, the IP69-rated enclosure provides protection against high-pressure, high-temperature water jets, steam cleaning and dust, ensuring compliance with stringent sanitation requirements in food and beverage facilities.

- Extended motor longevity: Advanced bearing protection reduces wear from electrical discharges, increasing motor lifespan, minimizing maintenance needs and maximizing uptime.

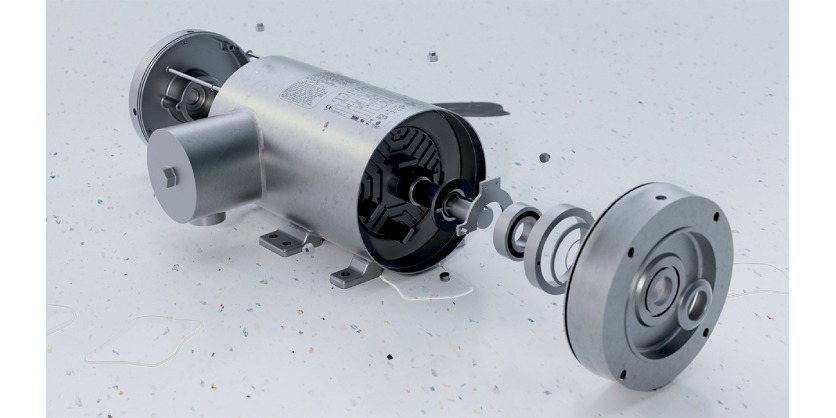

Other features standard on Baldor-Reliance Food Safe stainless steel motors:

- 360-degree rotatable conduit box for ease of installation, operation and maintenance

- Removable drain holes allow for a completely sealed or continuously draining motor to best suit the application

- All stainless-steel construction – including housing, conduit box, drain plugs, hardware, fan cover and endplates – safeguards against corrosion to avoid costly downtime and repairs

- IP69 laser-marked nameplate for readability throughout the life of the motor

- Hardened epoxy resin encapsulation provides an additional layer of internal protection against water and humidity

- Two-barrier mechanical shaft seals prevent water from entering at the shaft extension of the motor

- High-temperature Class H insulation with low-temperature (Class B) rise for longer insulation and bearing life

*as identified by the International Electrotechnical Commission (IEC) technical specification IEC TS 60034-30-2 (2016), which specifies the efficiency classes for variable speed drive (VSD) motors (i.e. motors which cannot be operated direct on line (DOL). IE5, currently the IEC’s most stringent efficiency performance standard, is recognized in Europe but also in North America by the National Electrical Manufacturers Association (NEMA) and the Consortium for Energy Efficiency.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 105,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Motion, a global leader in motors and drives, is at the core of accelerating a more productive and sustainable future. We innovate and push the boundaries of technology to contribute to energy efficient, decarbonizing and circular solutions for customers, industries and societies. With our digitally enabled drives, motors and services we support our customers and partners to achieve better performance, safety and reliability. To help the world’s industries outrun – leaner and cleaner, we deliver motor-driven solutions for a wide range of applications in all industrial segments. Building on over 140 years of domain expertise in electric powertrains, our more than 22,000 employees across 100 countries learn and improve every day. go.abb/motion

More Information

ABB Optimizes Baldor-Reliance Food Safe Stainless Steel Motors with Three-Lead Design

ABB, one of the world’s leading manufacturers of NEMA motors, has elevated its Baldor-Reliance® Food Safe stainless steel motor product portfolio with a streamlined three-lead electrical connection design, delivering a superior experience for food and beverage processing operations. This new motor solution is engineered to simplify installation, enhance reliability and improve workplace safety – all while seamlessly integrating with existing 460V systems.