Helping Industries Do Better with Generative AI: ABB Launches Genix Copilot with Microsoft

December 12, 2024

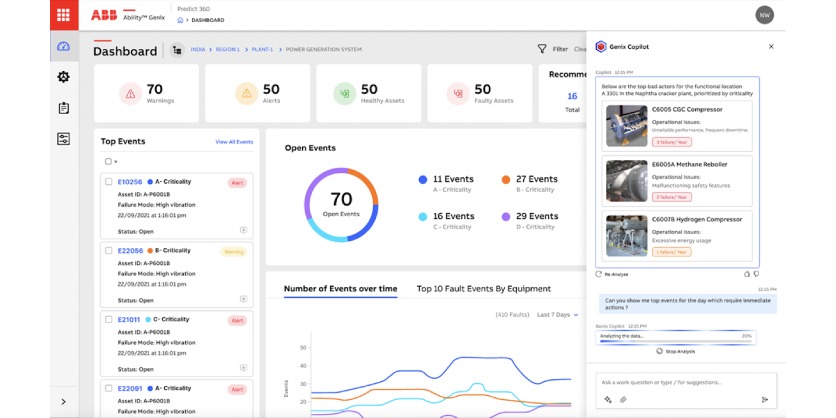

- ABB Ability™ Genix Copilot integrates generative AI to boost productivity, efficiency and sustainability in industrial operations, helping critical assets perform better

- The solution processes real-time data from multiple sources, providing instant alerts, predictions and recommendations for improvement through an intuitive user interface

- Through its ongoing collaboration with Microsoft and leveraging Azure OpenAI Service, ABB has developed multiple use cases based on Genix Copilot that are already seeing early adoption

Building on its long-standing collaboration with Microsoft, ABB has launched ABB Ability™ Genix Copilot, a generative AI solution that helps energy, utilities and other industries improve efficiency, productivity, and sustainability by contextualizing vast amounts of data and providing actionable insights in an intuitive manner.

Genix Copilot utilizes large language models such as GPT-4, customized for industrial use cases. Unlike traditional natural language processing that works primarily with text, Genix Copilot uses real-world data from the production environment, providing insights that can be immediately implemented to improve industrial operations.

ABB estimates that by embedding Genix Copilot capabilities into its industrial digital solutions, customers can achieve significant cost savings in operations and maintenance, boost production efficiency, and drive improvements in sustainability metrics such as optimized energy use and reduced emissions.

“At ABB, digitalization and AI are at the core of delivering more value to our customers, with a substantial part of our R&D workforce dedicated to digital, AI and software. Collaboration of ABB and Microsoft on generative AI is an important step in driving innovation and shaping the future of industry, helping our customers outrun – leaner and cleaner,” said Peter Terwiesch, President, ABB Process Automation. “With Genix Copilot, we can bring a new era of user experience, collaboration and consumerization of real-time actionable insights across roles. By embedding Genix Copilot capabilities in our Genix solutions, we’re empowering customers to make faster, data-driven decisions that help them improve productivity, efficiency and sustainability.”

“Working with ABB, we’re truly pushing the boundaries of what generative AI can do for industry. Genix Copilot has the potential to transform industrial operations, offering customers a practical, easy-to-use tool that enhances efficiency, productivity and sustainability,” said Sonja Meindl, Enterprise Commercial Director, Microsoft Switzerland.

Genix Copilot architecture is designed to handle and process data from multiple sources, including shop floor operations, operator conversations, enterprise systems, unstructured data and metadata, to deliver comprehensive insights with natural language support.

The intuitive conversational interface allows users to inquire about various operational parameters, such as asset health, performance, fault analysis and more, receiving clear and concise responses. For example, a maintenance manager can request a summary of the day’s events for their plant, including insights on critical assets that may require attention, root cause analysis as well as the status of the work orders.

Genix Copilot provides a role-based user experience, offering real-time actionable insights to various functions across an industrial organization – from executives in the boardroom to specialists analyzing performance metrics, and engineers troubleshooting equipment. With a strong emphasis on safeguarding data, the solution enables capturing an operator’s knowledge and facilitates collaborative decision-making across roles.

Three use cases already seeing early adoption:

- Genix Asset Performance Management Copilot delivers an intuitive user experience for maintenance teams in asset-intensive industries, providing real-time insights in natural language, summarizing key events, as well as delivering contextual analytics and actionable recommendations. With predictive maintenance insights, it helps to improve asset performance and minimize downtime.

- Genix My Measurement Assistant Copilot streamlines troubleshooting and maintenance for industrial devices by leveraging AI to quickly access relevant documentation, error codes and spare part details.

- Genix Sustainability Insights Copilot supports industries in monitoring and enhancing sustainability efforts by providing actionable insights on energy consumption and emission management.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 105,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

Related Story

ABB Co-Launches Interoperability Initiative to Unlock Industrial IoT Insights for More Efficient and Sustainable Industry

At the Hannover Messe on April 23, 2024, founding members ABB (including B&R), Capgemini, Microsoft, Rockwell Automation, Schneider Electric (including AVEVA) and Siemens announced collaboration on a new initiative to deliver interoperability for Industrial IoT ecosystems.