IndustrialPI from Pilz: Versatile Industrial PC for Automation and Drive Technology – Convertible: IIOT Gateway or Soft PLC

October 23, 2024

With IndustrialPI, Pilz is introducing an open, modular industrial PC. It has freely available open source software and offers numerous input and output modules. As a result, the industrial PC can be used as a gateway in Industrial Internet environments (IIOT) or as a Soft PLC in the widest range of applications. IndustrialPI represents an easy-to-use solution for the implementation of Industry 4.0 concepts.

As an IIOT Gateway, IndustrialPI is easy to incorporate into existing system architectures. It collects process or operational data, for example, in the immediate vicinity of plant and machinery, and transfers it directly to a company cloud. This gives users a permanent overview of their plant and machinery, wherever they are.

Standard controller for diverse automation projects

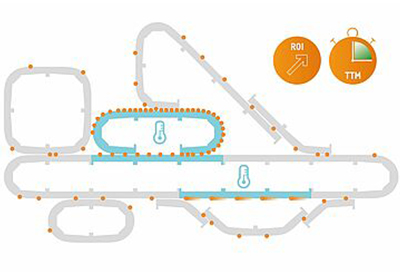

As a Soft PLC, IndustrialPI can also control plant and machinery. Potential applications are portal machines used to sort battery cells or carton erectors in the packaging industry. In this case, IndustrialPI functions as a standard controller for automation and drive technology and can be used for the widest range of automation projects. These include pure control applications, as well as synchronous axis movements in a machine’s powertrain. Thus IndustrialPI rounds off the Pilz offer for complete automation solutions.

Automation and safety

This new Industrial PC from Pilz is available in two different versions: the first is the IndustrialPI 4 with 4 GB RAM, 32 GB eMMC data memory and 64 Bit operating system. It is particularly suitable for automation applications as a Soft PLC. The other is the IndustrialPI 4 Wifi (8 GB RAM, 32 GB eMMC, 64 Bit OS). This can be used as a gateway, data collector and diagnostic unit in conjunction with the safe small controller PNOZmulti 2 and the automation system PSS 4000 from Pilz.

The result is an industrial solution for data exchange between the Internet of Things and Cloud Services

IndustrialPI is thus flexible and individually usable. Customised application supports users with regard to costs.

Proven concept, implemented for industry

IndustrialPI is based on the Raspberry Pi, familiar from private use. However, it has a tough housing, robust mechanics, and is equipped with industrial-grade electronics. As such it meets the requirements of highly available industrial control technology in accordance with EN 61131-2. As with the Raspberry Pi, it is based on the open source concept. An operating system specifically tailored to the IndustrialPI is installed out-of-the-box, and includes the user-friendly development tool Node-RED.

Related Story

Safety for Human and Machine: Pilz Services

Pilz services supports your business with their services in the field of machinery safety and automation. Benefit from their extensive portfolio, which includes consulting, engineering and training. Implement your safety and operational goals with their help. Their service specialists provide increased safety around the world.