Hirebotics Marks Major Milestones at IMTS 2024

October 11, 2024

By Krystie Johnston

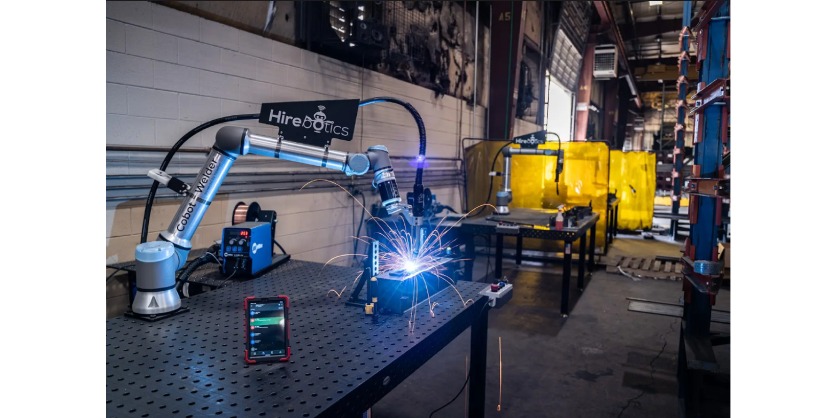

Hirebotics recently showcased their latest innovations at IMTS, including their Beacon platform which makes programming a cobot as easy as using a cell phone or tablet, and unveiled new features designed to enhance the capabilities of their Beacon-powered cobots.

Empower the Metal Workers You Already Have

Many automation solutions on the market today require that end users have knowledge of robotics from a programming standpoint. Hirebotics’ mission is to change this by empowering end users with cobot solutions for metal fabrication that are accessible, easy to use, and intuitive. The company recently highlighted their solutions at IMTS, the largest tradeshow for manufacturing technology in the Western hemisphere and celebrated receiving Universal Robot’s Global OEM of the Year Award.

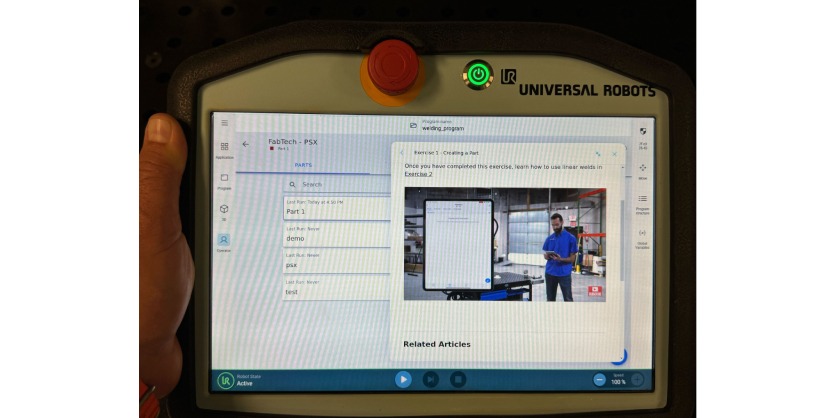

Hirebotics demonstrated their Beacon software and announced that it is now able to support Universal Robot’s Polyscope X platform. Manuel Sordo, Chief Commercial Officer at Hirebotics explains why this development is so important. Beacon allows end users to teach cobot welders to perform various tasks with a phone or tablet. This approach to automating is vastly different from their competitors and is making automation more accessible than ever.

“There is an increasing need for automation in welding. Welding by industrial robots has existed for many, many years, but there is another part of welding that has been dependent on labour and needs to be better qualified. There are less and less people in this field, and there is a gap for those applications with high mix and low volume of parts,” Sordo explains. Industrial welding robots have their place – they are great for high-volume production such as the automotive industry – but they are not the best fit for high-mix-low-volume applications that small to medium enterprises see most often.

For these applications, it is not feasible for the company to purchase an industrial robot, go through the process of automating it, and then, in a months’ time or less, have to start over because the part or the task that the robot is working on has changed. Industrial robots are big and bulky, and inflexible for high-mix-low-volume applications. Moreover, programming them can be incredibly complicated.

Industrial-grade cobot welding with consumer-level ease-of-use at a phenomenal price point

Hirebotics recognized cobots are an ideal fit for companies looking to automate their welding workflow. They also recognized that these manufacturers have skilled welders but may not have skilled robot programmers. To address this, they created a solution that offers automation technology that is easy to use. Any welder, without having any experience with robots, can use it in their operations with absolutely no programming, and take advantage of having a cobot welder that fits their application and is flexible enough to adapt as operations change.

Sordo says that there are other technologies available on the market that automate welding, but what sets Hirebotics apart is how easy their solution is to use. “You just download an app on your phone, select the welder type that you want, determine the points of trajectory for the robot, and you can have a perfect weld. There are technologies out there that still require some level of knowledge in programming robots, to the point that, if you want that perfect weld, you really need to go into the programming aspect. And that calls for companies to have somebody who knows about programming, and that is going to be a hassle every time you introduce new parts into the system.”

Ready For Production In Minutes, Not Hours

With companies already facing a shortage of skilled workers, empowering welders to supplement their work with cobot welders improves speed, efficiency, and throughput. With Beacon, Hirebotics eliminates the need for programming knowledge or pendant experience by making it as easy to use as possible to achieve automated systems that end users can leverage immediately. Moreover, Beacon can be used for cutting applications as well, as its interface is focused on the weld/cut path, wire feed speed (WFS), stickout, and other settings critical for fabrication.

At the show, Hirebotics’ launched exciting new features designed to enhance the capabilities of their Beacon-powered cobots. “One of them is being able to use this technology on Polyscope X by UR. Another involves improvements we have made to the power source of our product, now we are offering our system with DeltaWeld by Miller. This brings an entirely new set of features and makes our system so much better,” Sordo says. With Beacon now available on UR Polyscope X, teaching cobots becomes more accessible than ever. Customers can use Hirebotics’ innovative teaching app wherever they want to – iOS, Android, the Web, and now on UR’s Polyscope X.

For companies that are looking to automate parts of their manufacturing processes, Hirebotics offers a complete, safe, simple solution that can help right away. Sordo explains that IMTS is a great opportunity for people to see their solution and try it themselves. “I think this is the only true, turnkey application – literally plug-and-play application – that requires absolutely no knowledge of programming that uses an actual robotic arm. Anybody can just pug it into the wall, set the part, and start welding with absolutely no knowledge of cobots, without ever having interacted with a cobot before.” For Sordo, nothing motivates him more than teaching people about these innovations and listening to customers’ pain points.

More Productivity. More Quality. More Customers.

Hirebotics has deployed more than 1,000 systems worldwide and continues to push the boundaries of what is possible in automation. Their drive to continually develop and deliver innovative, easy to use solutions that empower metal fabricators is unyielding. Sordo says their success is not based on their ability to provide a robotic arm that can weld or cut metal well; it is about providing a solution for their customers.

As a testament to this claim, Hirebotics received Universal Robots’ Global OEM of the Year Award for the second year in a row for the most robot sales across all application segments and geographies. “Through the OEN Program, UR wants to, in a way, push the confidence [of their partners] to develop solutions and sell those solutions to end users. Ideally, by offering a completely full turnkey solution for different applications. This is where we want to take Hirebotics, and this award shows our fast, rapid growth, and that we have developed a solution that is applicable, is being used by hundreds and hundreds of users, and is giving them amazing results.”

Sordo addresses the concerns he hears from people in the industry about automated cobot welders replacing jobs and negatively impacting the industry. But he believes that people still have a significant role to play in this field. He has a personal outlook on this debate because he has family currently in school, taking welding. The current situation is that there is a shortage of qualified welders, and this job is an essential part of the manufacturing industry. For example, in the United States, the median age of a welding technician is 55 years of age, with only about 20% of the total welders under the age of 35. Solving the shortage will require more than one solution.

Welding will experience changing technologies and innovations, but it still needs people to make it work. What Sordo sees coming is this career transforming. He sees it happening right now. “We just got a huge order from one of the universities that wants to take our system and teach the students how to use robotics to make welds. We are taking the next step in that craft and making it in a way that is more viable for manufacturing companies so that we can grow those companies and grow with more job opportunities for those welders that are becoming welders and will also be able to administer and mange robotic welding cells.”

Conclusion

Hirebotics has made it their mission to provide metal fabrication cobot solutions that are accessible for everyone. From welding to plasma cutting, their unique approach to cobot programming and their relentless pursuit for improving these processes is transforming applications around the world. Backed by a network of partners, they are ready to help you scale your business, improve production quality, and break out of the existing backlog.

Interested in learning more? Explore what Hirebotics has to offer today.

Related Story

Hirebotics, Universal Robots OEM of the Year, at IMTS 2024

Hirebotics was recently awarded Global OEM of the year by Universal Robots (UR). This award for the most robot sales is for UR’s top OEM partner across all application segments and geographies.

“We are deeply honored to be named Universal Robots’ OEM of the Year for a second year in a row. Being the recipient of this global award is a significant milestone for Hirebotics, and it reflects the dedication and innovation of our entire team. Our partnership with Universal Robots has allowed us to push the boundaries of what’s possible in automation, and this recognition inspires us to continue delivering cutting-edge, easy-to-use solutions that empower metal fabricators worldwide.” – Rob Goldiez, CEO of Hirebotics