Komatsu and ABB Collaborate Through Open Electrification Platform

August 14, 2024

Innovation is the primary catalyst for ABB and Komatsu to help the industry reach carbon reduction goals

ABB and Komatsu are developing innovative solutions such as fully electrified mining machinery and advanced energy management systems. Innovation is the primary catalyst for ABB and Komatsu to help the industry reach carbon reduction goals. Each company will nominate specialists from their teams for a working group to develop recommendations and strategies on what the road to net zero emission systems for grid to wheel could require.

“We’re pleased to embark on this collaboration with ABB and are excited to leverage one another’s industry leading products and technological expertise to help move mining operations toward net zero emissions, empowering a sustainable future where people, business and the planet thrive together,” said Dan Funcannon, Sr. Vice President of Surface Haulage for Komatsu.

“By working together, we will tackle electrification and make a revolutionary difference to the way mining companies operate their sites in the near future,” said Joachim Braun, Division President, ABB Process Industries. “We recognize the strategic importance of this agreement and believe there will be mutual business benefits and potential technology solutions for the mining market. Collaboration across the industry has already been proven to enable real and faster progress and we look forward to driving what happens next.”

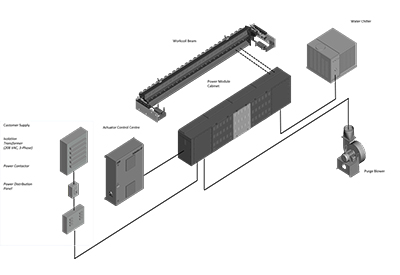

For a firsthand look of this collaboration, ABB’s Robot Automated Connection Device (ACD) will be featured on the Komatsu MINExpo 2024 booth from September 24th to 26th. The Robot ACD is planned to be a fully automated interoperable connection device working in tandem with the ABB eMine™ FastCharge solution for future battery-electric trucks.

ABB draws on 130 years of experience in the mining industry and is a pioneer in the integration of electrification, automation and digitalization in mining.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.www.abb.com

[1] Climate risk and decarbonization: What every mining CEO needs to know | McKinsey

More Information

ABB eMine™. For your world, and mine.

Real Progress is helping the Mining industry through the energy transition

Related Story

Antofagasta Minerals Partners with ABB to Drive Real Progress in Its Mining Industry Decarbonization Initiatives

The mining industry is striving to close the gap in demand for copper driven by the energy transition, while simultaneously wrangling the challenge of decarbonizing their own operations. Currently, anticipated mine supply from announced projects is expected to meet only 70 percent of copper requirements by 2035[1]. Net zero emission haul trucks have been identified as a key solution for achieving large scale decarbonization for mines around the world. This collaboration between ABB and Antofagasta Minerals represents a significant step toward advancing the adoption of electrification in mining and defining best practice for the industry.