ABB Creates World’s First Medium Voltage, Speed-Controlled Motor Concept, Facilitating Industry’s Contribution to a Low Carbon World

June 11, 2024

- New concept introduces complete speed control for an MV motor in a single energy efficient package

- High improvement potential as 10% of the world’s electricity is converted into motion by large motors

- Solution will offer energy savings of up to 40 percent for pumps, compressors, fans and other applications across multiple industries

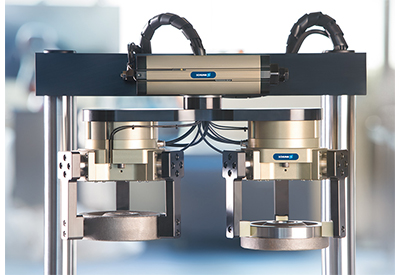

ABB’s MV Titanium concept is the world’s first medium-voltage (MV), speed controlled, industrial motor, in the 1-to-5 megawatt (MW) range that brings connectivity and control features in an easy to specify and install package. The all-in-one concept brings the benefits of energy efficiency to MV motor-driven processes, which today account for 10% of the world’s electricity.

“Energy efficiency measures of speed-controlled motors have gained significant traction in small size motors, for low voltage applications. But large motors have so far been left behind, due to initial cost and complexity, with only 10-15 percent currently connected to a drive,” says Heikki Vepsäläinen, President of ABB Large Motors and Generators.

“But that is set to change with our new MV Titanium concept that makes it cost-effective and straightforward to install a suitable matched motor, with increased control, monitoring, and connectivity in a single package. It is the right upgrade solution for existing direct-on-line motors. And the potential savings in energy costs and CO2 emissions are huge – if we retrofitted the entire installed base, it would be like taking just over 1000 coal-fired power stations offline.”

In this pursuit, ABB has developed the MV Titanium concept to address the main perceived obstacles related to installing a drive with a large motor. These include not only the initial cost of a separate drive, but also its associated electrical house (e house), transformers, switchgear and cabling that multiply the capital cost and increase the complexity of installation, especially on existing sites where space is at a premium. In addition to these savings, it will also provide OPEX savings due to the energy efficiency it will provide.

The next-generation concept has been built on ABB’s 140 years of motor design and 50 years of drives technology experience to create a solution that integrates energy efficiency, controllability, and connectivity into a single package. Furthermore, it has intelligence built in, with analytical and connectivity capabilities so it can seamlessly integrate into existing systems, as well as providing software libraries and interfaces for process monitoring and optimization.

The MV Titanium motors are intended for use with pumps, compressors, and fans as typical applications, where they could reduce energy consumption by up to 40 percent as well as enhancing productivity and minimizing downtime. They will be used across a wide range of sectors including power and renewables, processing, mining, cement, and water. Heikki Vepsäläinen concludes: “Beyond its technical progress, this next-generation motor concept represents a significant step towards productivity in a low carbon world. It puts ABB well on the road to support changing large, fixed speed motors to fully electrically controlled motors, one by one.”

ABB (ABBN: SIX Swiss Ex) is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered, and operated. Building on 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

ABB Motion, a global leader in motors and drives, is at the core of accelerating a more productive and sustainable future. We innovate and push the boundaries of technology to contribute to energy efficient, decarbonizing, and circular solutions for customers, industries, and societies. With our digitally enabled drives, motors, and services we support our customers and partners to achieve better performance, safety, and reliability. We deliver motor driven solutions for a wide range of applications in all industrial segments. Building on over 140 years of domain expertise in electric powertrains, our more than 22,000 employees across 100 countries learn and improve every day. go.abb/motion

More Information

Related Story

ABB Energy Appraisals of Industrial Electric Motors Reveal Potential 2.1 Twh Lifetime Savings

From June to September 2023, ABB analyzed more than 2,000 industrial electric motors under its Energy Appraisal service and has identified an average energy saving of 31 percent. That equates to more than 2.1 terawatt-hours (TWh) of potential energy savings across the 20-year lifetime of these systems. Energy appraisals enable industrial businesses to pinpoint exactly where their biggest energy savings lie across fleets of motor-driven systems.