The Story of How SmartD Revolutionized Motor Control for the 21st Century

May 28, 2024

By Krystie Johnston

To reinvent the wheel is to attempt to duplicate something that has already been created, most often with superior results. SmartD has not reinvented the Variable Frequency Drive (VFD). They have revolutionized it.

When Simon Leblond, CEO of SmartD Technologies Inc. and his co-founders set out to start a new company, they did not know that they would be revolutionizing the way we approach motor control. Leblond has twenty years of experience developing successful startups but knew nothing about VFDs when he started SmartD. About six years ago, he and three colleagues started the company, not really knowing what it would do.

“We kind of did what I tell every startup founder not to do. When I coach startup founders, I always tell them to start with a problem and then find a solution to it. We started with a technology: wide-band gap semiconductors, specifically Gallium Nitride (GaN) and Silicon Carbide (SiC). These are revolutionary semiconductors for power electronics; they can switch much faster with much lower losses [than conventional materials]. And as my co-founders and I were looking at different opportunities, we really felt that we were at an inflection point for these semiconductor materials, so we started looking for applications for them.”

Leblond and his team explored several different uses and opportunities for these new semiconductor materials: they looked at using them for protection in electrical cabinets, more specifically using them for solid-state breakers. They worked on mockup products for months, investigated what other companies were working on at the time, and visited potential customers like panel builders and original equipment manufacturers (OEMs). They showed them their virtual specification sheets that incorporated GaN and SiC in the power electronics and asked for their opinion about these products.

“Very quickly it became apparent that just protection did not have enough value to justify the extra cost of using Silicon Carbide to replace mechanical breakers or fuses, so we started looking at adding features to the pure protection play. We quickly converged on motor control as a place where there were enough elements to potentially justify the extra cost. As we gradually went through different motor control configurations, we discovered these big bulky things called filters that were in VFD panels,” recalls Leblond.

And that is when the Eureka moment happened. After visiting one panel shop after another and learning about VFDs and the use of filters to mitigate their side-effects, Simon Caron, one of the co-founders proposed miniaturizing the filters using the higher switching frequency enabled by SiC.

“We sat down, me, Simon Caron, and our other two co-founders, Jean-Marc Legrand and Jonathan Brodeur, who are responsible for software and hardware, respectively, and we said, ‘It kind of seems clear that the path to bringing a revolution to the market is to first focus on the filter in the VFD world.’ But doing a VFD is no walk in the park; it is one of the most complex products you can think of. It has high-speed, power electronics, IoT, etcetera. We asked, ‘Are we ready for this?’”

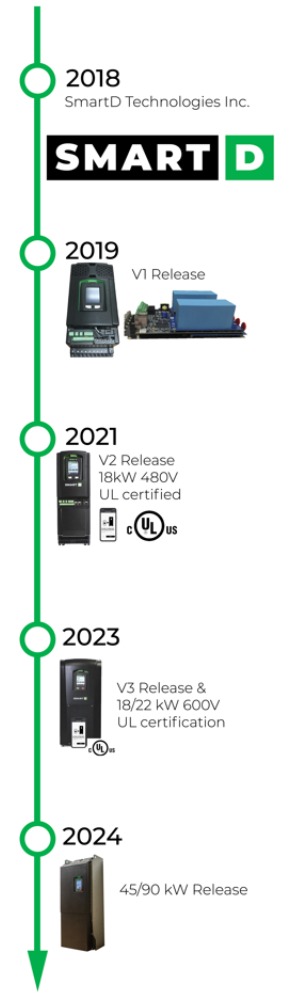

The answer was of course, yes. The team was well-versed in creating startups and were up for the challenge to create a before and after impact on the industry. And they jumped at the opportunity. Leblond describes some of the hard work that has been put into developing their SmartD technology. They had to redesign their control algorithms to consider filters in the product, redevelop the full software stack for a VFD from scratch using modern architectures and tools. They had to develop new software that uses open-source programming language and will be ready to manage the challenges of cybersecurity and the Internet of Things (IoT).

“We really had to start with a white page. And that is what has enabled us to come up with this new concept. I think if we were part of one of the large leading players, it would have been very hard to undo all the industrial optimization around their VFD,” says Leblond.

For Leblond and his team, it has been a challenge, but also an opportunity. They have progressed from proof of concept to a complete product, that is now their framework from which they can go to other power levels. Leblond says, “It has been fun to go back to customers over and over and show them the iterations and go from, ‘You are missing this and this.’ to ‘This is okay now. Now we can use it. When do you release your next power level?’”

What Leblond and his team have achieved in just over five years is impressive. They have grown from four to more than forty employees and are prepared for further growth. “We have five motor test benches ranging from a few kilowatts to 165 kilowatts. We keep on putting more amperage into our building. Every time a tenant moves out, we open up a wall and expand the offices – whether it is in the lab or the office area,” says Leblond.

SmartD is located in Montreal, Quebec, just between Griffintown and downtown. Their building is one of the last standing industrial buildings in Griffintown and is a symbol of the area’s vibrant history. At this location, they are within walking distance of École de technologie supérieure (ETS) and Concordia University, two of their research partners. They also recently completed a funding round, securing 14.2 million from investors such as Investissement Québec (IQ), Hammond Power Solutions (HPS), SE Ventures, and Boreal Ventures.

It is evident that SmartD is poised for growth. “We have about a dozen distributors that have signed up with us both in Canada and the US. We work with distributors, their footprint, their connection. We have a preference for distributors that have their own automation specialists on staff so that we can train them, and they can support their own customers that way. We ensure tier three technical support and customer service that way. It is also a good way for us to scale,” says Leblond.

Leblond and his team have an energy about them that comes from being on the verge of something great. And there are many companies who support SmartD. As the market becomes more aware of their clean power VFDs, they will continue to grow. “We have the right partners for this journey. They believe in where we are going. They have visited us, they see what we are doing, they believe in the growth story and want to be sure that funding and support are available as this takes off. I’m super excited with what’s ahead for SmartD.”

More Information

Related Story

SmartD Innovation Goes Public! Test Their Game-Changing VFD Technology for Free

SmartD Technologies is thrilled to announce that Innovation Solution Canada has selected SmartD to have their revolutionary variable frequency drive (VFD) technology tested by public and governmental institutions across Canada! This is your chance to deploy and experience the future of motor control, test their Game-Changing VFD Technology for Free!