Despite Headwinds, Off-Shore Wind Energy Is the Future

May 22, 2024

Why Offshore Wind Power is the Future of Renewable Energy

Aside from hydropower, wind energy farms are currently producing the most clean, renewable energy worldwide. And unlike hydropower, the potential for growth is substantial. Wind could supply more than one-third of global electricity demand by 2050, according to the International Renewable Energy Agency (IRENA). Reaching this target will require embracing relatively new offshore wind technologies and overcoming logistical hurdles, but numerous advantages point to offshore powering the future of renewable wind energy.

The Lay of the…Ocean?

Offshore wind turbines generate more electricity per unit of capacity (size of the turbine) than land-based wind systems because of higher and more consistent wind speeds over the ocean. But building and maintaining offshore wind farms isn’t easy. In addition to harsh weather, offshore installations must cope with corrosive saltwater, complex construction and maintenance logistics, and a shortage of specialized workers.

Plus, an electrical grid doesn’t exist offshore, so investments in transmission are required in addition to potential upgrades of the onshore infrastructure. These factors increase the costs and risks of offshore wind projects; in 2018 the average cost of offshore wind power was around $0.13 per kilowatt-hour (kWh), compared to $0.06 per kWh* for land-based wind power.

Despite these challenges the benefits of offshore wind should soon outweigh the costs. As technology matures and the industry scales up, costs are expected to decline and reach parity with land-based wind power by 2030*. Meanwhile, several advantages may eventually make offshore more attractive than land-based wind power.

Timing is Everything

Compared to traditional energy sources, the most obvious drawbacks of wind power are variability and intermittency. Utilities can’t simply dial up more power from a wind farm when they need it, and if winds are strong but demand is low, production may need to be curtailed. Storage technologies can help smooth supply and demand, but that requires additional investment. It turns out the time-of-day offshore wind farms produce the most power is one of their biggest advantages.

Offshore wind tends to be stronger during the day and evening, when electricity demand is highest, while land-based wind is stronger at night, when demand is lowest. This more favorable wind profile reduces the need for backup or storage systems because electricity can be used as it’s produced, improving the likelihood of harnessing peak production on especially windy days. Less reliance on storage can help utilities save money that may not be factored into land vs sea cost comparisons.

Proximity to Power

Traditionally, a challenge for wind power is its location. Most of the best wind resources are located far away from the major load centers where electricity is consumed. For example, in the United States, some of the best wind resources are located centrally in the Great Plains, while most of the population is concentrated on the east and west coasts. Harnessing these resources requires long-distance transmission lines, which can be costly, inefficient, and difficult to build due to regulatory barriers.

So, counter intuitively, one of the advantages of offshore wind is geographical. Since most of the world’s population lives near the coast, offshore wind farms can more directly connect to the grid where the energy is consumed. This reduces the need for super-long land-based transmission lines and minimizes transmission energy losses. In fact, more than 80% of the current global electricity demand could be met by offshore wind power within just 60 kilometers of the shore. *

Bigger is Better

A fundamental truth of turbine design is that bigger really is better for power generation. But because of limited space, higher noise, and visual impacts, there are constraints on the size of wind turbines that can be installed on land. Moreover, transporting large blades – some approaching 100m in length – to the site can be challenging and prohibitively expensive. Even using special trucks and train cars, negotiating curving roads and tracks to access remote wind sites places practical limits on size.

Offshore wind power does not face the same limitations. Wind farms can be built on larger areas with more distance between each unit, allowing for bigger and more efficient turbines. In fact, as of 2022 the typical capacity for new offshore wind turbines was 8+ megawatts (MW), compared to 3-4 MW for land-based units*. Transporting huge turbine components by ship is also easier and cheaper than truck, allowing manufacturers to scale up designs. The newest commercially available offshore turbines are 15 MW monsters, and proposed designs are pushing 20+ MW!

How Does This All Work?

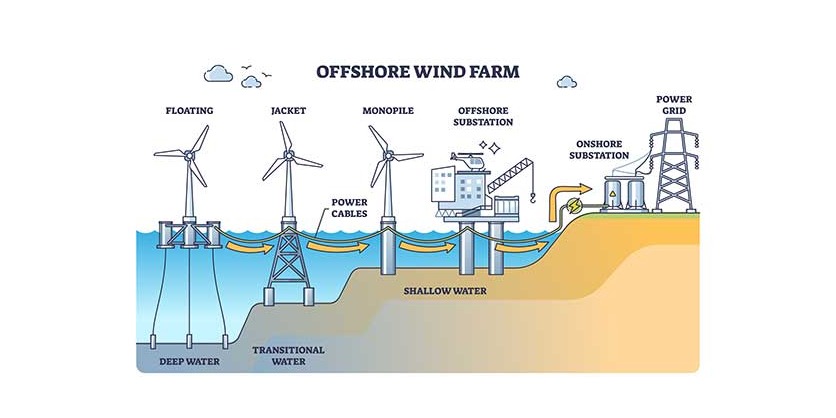

The best approach depends on the water depth and sea conditions. In shallow waters, fixed-bottom turbines with monopile supports are the proven and cost-effective option. Slightly deeper waters use jacket supports like oil rigs. These attach to foundations driven or drilled into the sea floor. But shallow depth sites are limited, so new floating turbines are a practical way to access wind resources in deeper waters. Floating base designs take multiple forms, but all are anchored to the sea floor with mooring lines to allow them to adjust to water movement and wind direction.

Undersea cables connect offshore wind farms to the power grid on land. These cables carry high voltage alternating current (AC) or direct current (DC) depending on the distance and capacity of the transmission. Solutions such as Panduit Uraprotect™ allow cables to withstand the harsh ocean environment and potential damage from anchors, fishing nets, or marine animals. Once onshore, the electricity is converted to the appropriate voltage and frequency at substations for integration with the grid.

The Tide is Turning to Offshore Wind Energy

Offshore wind energy generation holds a lot of promise for producing abundant clean electricity near the populations creating demand. While some technical, logistical, and environmental challenges still need to be addressed before wide adoption, considerable advantages point to offshore as the main growth driver for the wind industry of the future. And with 64GW** of offshore generation already installed, the future will be here before we know it.

As you develop your next project, Panduit is here to assist! Connect with a Renewable Energy Expert or explore Panduit’s wind energy solutions to learn more about their products and services.

*IRENA

**Global Wind Energy Council

Related Story

Panduit Receives Canada Standards Association Certification for its Cable Cleats

Panduit, a global leader in innovative electrical and network infrastructure solutions, announces it has successfully complied and received certification for its cable cleats in accordance with the recently published technical standard by the Canadian Standards Association (CSA). CSA C22.2 No.61914:23 Cable Cleats for Electrical Installations, was published in early October 2023. This achievement underscores the company’s ongoing dedication to providing cutting-edge, safe, and reliable solutions to meet the ever-evolving demands of the industry.