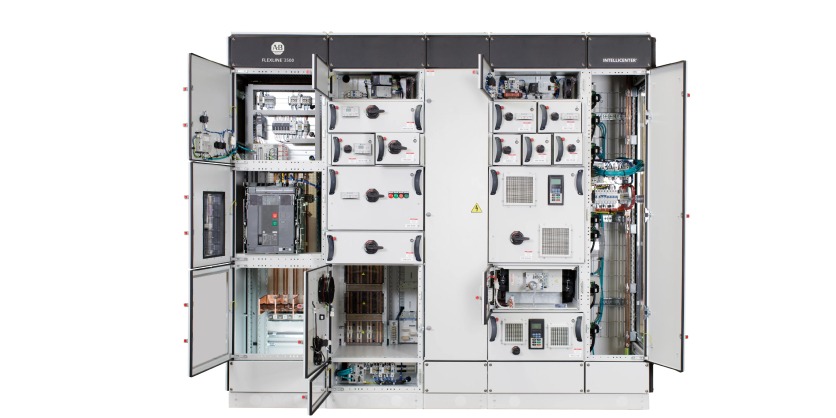

Rockwell Automation Reduces Downtime with New FLEXLINE 3500 Motor Control Center

May 7, 2024

Rockwell Automation reduces downtime with new FLEXLINE 3500 Motor Control Center. The new Allen‑Bradley® FLEXLINE™ 3500 low voltage motor control center (MCC) recently launched for IEC markets. The MCC is engineered to integrate motor control and power distribution into one centralized package, meeting IEC standards 61439-1&2. The smart devices in FLEXLINE 3500 MCCs help reduce unplanned downtime, maintenance and energy costs, plus engineering and commissioning costs. They also help improve production throughput and personnel safety. The FLEXLINE 3500 is engineered to match a wide range of motor control applications for various industries. Additionally, this MCC is designed for scalability and flexibility to meet variable installation footprints.

The FLEXLINE 3500 motor control center is now available for order.

More Information

For specifications and detailed product information, visit rok.auto/flexline

Related Story

Rockwell Automation to Increase Scale and Scope of AI in Manufacturing with NVIDIA

Rockwell Automation. one of the world’s largest companies dedicated to industrial automation and digital transformation, has announced it is collaborating with NVIDIA to accelerate a next-generation industrial architecture.