ABB and Imperial College Extend Carbon Capture Collaboration to Support Future Workforce and Energy Transition

November 1, 2023

- ABB and Imperial College London signed a 10-year contract to continue their carbon capture technology partnership

- Plant at Imperial College equips workforce for net-zero and helps tackle science, technology, engineering and mathematics (STEM) shortages, with 4,500 students having already used it since 2012

- The only teaching facility of its kind in the world uses over 250 instruments and sensors to measure and relay data to a distributed control system, replicating realistic operating conditions

A dedicated carbon capture pilot plant will continue to train the net-zero workforce, and engineers and scientists of the future, after ABB and Imperial College London signed a 10-year contract to extend their successful partnership. The plant is the only one of its kind in an academic institution in the world.

More than 4,500 students have had hands-on experience of ABB’s technology solutions at the plant since it opened in 2012 at Imperial College, which is one of the world’s top ten universities1 with a reputation for excellence in science and engineering.

With the agreement, ABB aims to equip today’s students with the skills needed to run tomorrow’s industrial processes by demonstrating how the latest technology can help to optimize plant performance and safely manage emergency situations in real-life applications. The collaboration between ABB and Imperial College gives the university access to some of the most advanced control and instrumentation technology available from any manufacturer.

“Extending the partnership with Imperial College allows us to offer students practical training to prepare them for a career in industry,” said Simon Wynne, Head of Energy Industries, ABB UK & Ireland. “A report by EngineeringUK2 says that for the UK to meet emissions targets by 2050, there needs to be a workforce, with the right STEM backgrounds, ready to respond to the energy transition challenge.”

Simon Wynne, Head of Energy Industries, ABB UK & Ireland

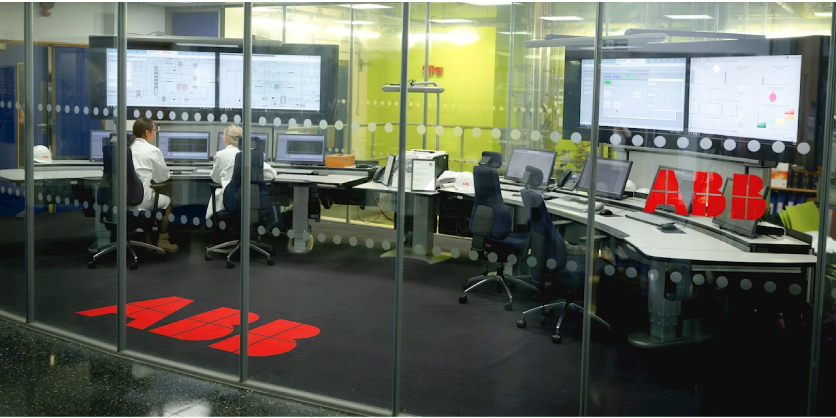

The plant, which is spread over four floors, uses ABB Ability™ System 800xA® for distributed process control and over 250 instruments, measuring temperature, pressure, carbon dioxide and flow. System 800xA automatically controls and coordinates all aspects of the plant process, which is then visualized on displays in the ABB Control Room where students can monitor and intervene if necessary.

ABB’s Ability™ Verification for measurement devices and new Ability™ SmartMaster verification and condition monitoring platform are also being used to equip students with the skills needed to optimize instrument performance through predictive maintenance.

“When we started the partnership with ABB, the aim was to encourage more people to go into and stay in chemical engineering,” said Dr Colin Hale, Senior Teaching Fellow at Imperial College London. “One of the ways to do this was to set up this carbon capture plant so we could enthuse students to follow through on the environmental topics they have learnt previously. ABB shares this collective vision.”

Dr Colin Hale, Senior Teaching Fellow at Imperial College London

“During my time in the carbon capture pilot plant, I have actively participated in the operation of the process, gaining a deeper understanding of the development and application of the technology,” said Yiheng Shao, fourth year undergraduate student at Imperial College London. “This experience has also bolstered my confidence in the role of carbon capture in achieving net-zero goals.”

Yiheng Shao, fourth year undergraduate student at Imperial College London

According to a report by S&P Global3, carbon capture and storage (CCS) can help decarbonize industry, reduce emissions and reach net zero, while the Global CCS Institute says in 2022 there was a 44 percent increase in the number of CCS facilities around the world compared with the previous year4.

To enable the commercial CCS market to scale, ABB is deploying technology solutions to lower the capital and operational investment costs and de-risk integration into existing and new operations. In March 2023 ABB joined forces with London-based Pace CCS to make the capture, transportation and storage of industrial carbon dioxide emissions more accessible. Key to this is using digital twin technology to provide a virtual replica of a real process to test scenarios and deliver proof of concept.

Earlier this year, the UK Government outlined its Powering Up Britain policy. This series of net-zero pledges, including £20 billion of funding to unlock private investment and jobs in CCS, aims to deliver an energy system with cleaner, more affordable energy sources.

About ABB

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Notes

- https://www.topuniversities.com/universities/imperial-college-london

- https://www.engineeringuk.com/news-views/new-analysis-highlights-lack-of-understanding-around-green-stem-jobs/

- https://www.spglobal.com/commodityinsights/en/ci/research-analysis/carbon-capture-ccus-ma-market-2022-oil-and-gas-companies.html

- https://status22.globalccsinstitute.com/2022-status-report/global-status-of-ccs/

Related Story

ABB Contributes to New Report Showing How Industry Can Reduce Global Carbon Emissions By 11% By 2030 While Saving $437 Billion Annually

As industry is facing the unprecedented challenge to meet global decarbonization targets while addressing growing demand, a new report from the Energy Efficiency Movement (EEM) demonstrates how businesses can start acting immediately. The EEM is a global forum founded by ABB, and now consisting of more than 400 organizations, that shares ideas, best practices and commitments to create a more energy-efficient world.