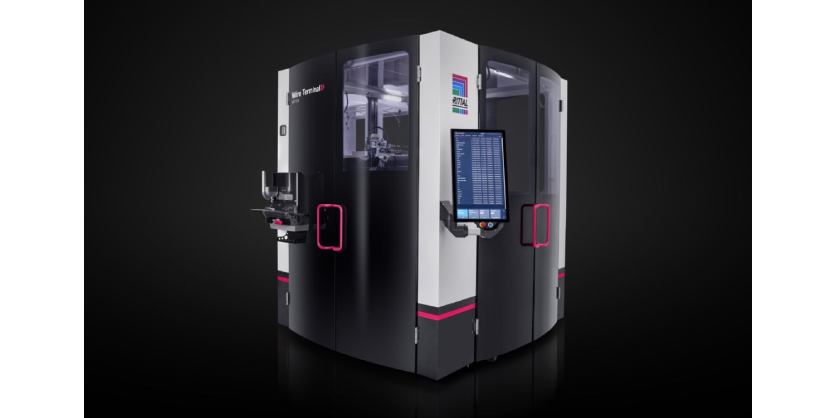

Wire Terminal WT C – Fully Automated Wire Processing Machine

October 3, 2023

The compact Wire Terminal C fully automated wire processing machine ensures efficient, cost-effective processing of your wires. Up to 36 different wires in cross-sections ranging from 0.5 mm² to 6 mm² may be processed fully automatically without retooling. Operations include length-cutting, infinitely variable insulation stripping, crimping of wire end ferrules in a variety of sleeve lengths and project-specific labelling of the wires. The wires can either be stored fully automatically in the controlled ordering system with cross-sectional wire rails, with space for more than 2100 wires, or produced in project-specific wire-chain bundles for downstream process stages.

The new Wire Terminal WT C5 and C10 are the latest generation of fully automated wire processing machines from Rittal Automation Systems, allowing wires to be assembled 10 times faster than by hand. The modular system with numerous optional add-ons is a state-of-the-art automation solution for panel builders and switchgear manufacturers, with a seamless data flow from engineering through to the wiring workstation.

In panel building and switchgear manufacturing, wiring is one of the biggest “time wasters”, accounting for around 50 percent of the processing time.

The “Wire Terminal C” fully automated wire processing machine from Rittal Automation Systems can significantly speed up this process.

More Information

Related Video

Wire Terminal WT C from Rittal – Fully Automated Wire Processing Machine

The new, compact Wire Terminal WT fully automated wire processing machines produce up to to 36 different wires in cross-section ranging from 0,5 mm² to 2,5 mm² folly automatically, with zero manual intervention. Make your wire assembly production process 8 times faster.