Why PMAC Controllers Are Essential for Manufacturers Looking to Reduce Costs and Increase Efficiency

October 2, 2023

Manufacturers in Semiconductors, Electronics, Automotive, Packaging, and Machine Tooling industries face pressures to reduce costs, minimize downtime, optimize space and flexibility, and increase production speed. The PMAC controller family has been able to transform manufacturers operations to meet these unique needs.

By providing engineers and programmers with real-time monitoring, modification, and control capabilities encompassing motion, IO, programming, and communication, it allows for high-speed operations and exceptional machine performance.

Omron helps us learn more about how these controllers are reducing costs and increasing efficiency.

1. A customizable design to meet their unique customer needs.

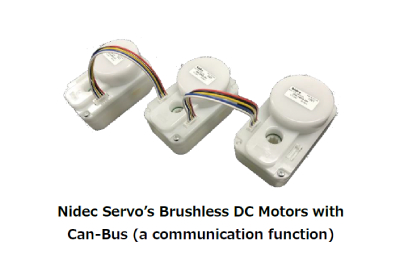

Manufactures have run into limitations on their current motion control system. There is a need for more flexibility to use specialized components such as drives, motors, encoders, to solve their complex applications with advanced machine precision. The PMAC platform is able to help manufactures implement specialized hardware that can create the machine design to meet their customers needs. PMAC has the ability to connect and control 3rd party products and integrate them into controller and solution extremely well. This level of versatility is invaluable in meeting the diverse needs of various applications.

2. Increasing efficiency across the board.

There are many ways in which efficiency can be measured. For instance, using less raw materials to reduce costs, maximize production during running time, or minimizing downtime between production runs. The PMAC makes this possible by encompassing features that are built into the hardware and firmware that allow manufacturers to design a very high speed and accurate machine. As manufactures work towards higher efficiencies and better throughput of their machines, features such as dynamic lookahead, spectral decomposition, and feedforward are essential to their operations.

3. Keep up with high market demands with PMAC Controllers.

It is often a struggle for manufacturers to produce product fast enough to keep up with the high demands of their market. PMAC features a solution by allowing production engineers to keep their machine running without needing to make any program changes. With the ability to swiftly switch between G Code files, parts can be changed instantaneously, providing flexibility and adaptability on the fly.

4. Optimizing their space.

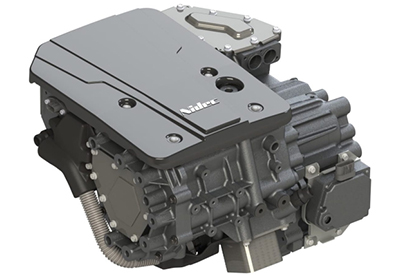

Manufacturers are moving to new smaller production areas, even beginning to manufacture in office atmospheres. This means that machines need to take up less space, be portable, and even be set on tables and desks. PMAC has a variety of form factors designed to allow flexibility in applying to each machine, including the CK5M Multi-Axis Controller. By offering this diverse lineup, it ensures that machine builders have the flexibility and adaptability necessary to address the unique requirements of each application.

More Information

Learn more about Omron’s PMAC platform

Related Product

Omron Enhances Information Security with IEC 62443-4-1 Certification

An industry-leading automation solutions provider, Omron Automation Americas, takes a significant stride towards bolstering information security for customer factories and production equipment. The company now is certified by the guidelines and requirements of IEC 62443-4-1 for establishing a secure development lifecycle for its Programmable Logic Controller (PLC) products and software.