Q&A With HELU: IP Rating

August 11, 2023

Q&A With HELU: IP Rating

Have you ever looked inside of a computer, cellphone or industrial control panel? If you have, you know that each contains a multitude of fragile electronic parts. Some of them are smaller than a grain of rice. In some cases, you might see a thin, shiny protective layer that protects these sensitive parts. This is called a conformal coating. If there is no coating, contaminants such as dirt, dust and water must be kept away from these parts by other means, such as barriers or seals that have specific protective ratings to ensure to the safety of the electronic device. Regional Sales Manager Stacey Green explains the nomenclature behind IP ratings and why they are important to electrical equipment.

Q: What does the IP stand for?

A: The abbreviation IP stands for Ingress Protection and indicates how well a device protects against water and dust. This is not for any enclosure, but one specifically intended for the safe operation of electrical equipment. Having a measurable performance characteristic provides validity when making a claim that a device is “water-resistant” and/or “dust-proof.”

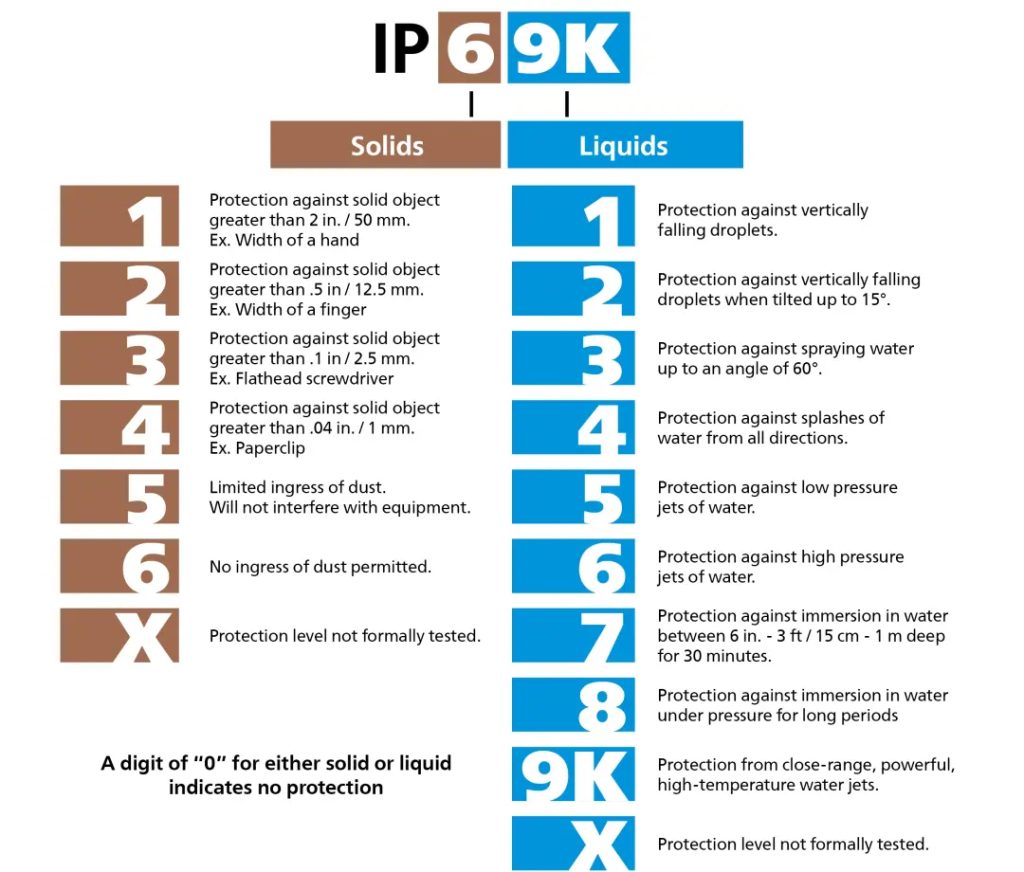

Q: What do the numbers mean?

A: The IP rating numbers show how well a container protects its electrical components from solids and liquids. The first digit after the “IP” is the level of protection from solids. The numbers used here are on a scale of 1-6, with one offering minimal protection and six offering the highest level of protection. The second digit is the level of protection from liquids. It is on a scale of 1-9K, again with one offering minimal protection and 9K offering the highest level of protection. In either case, if the number zero is shown there is no protection. In some instances, you will find a third letter that usually provides additional information, but this is optional and not commonly used.

Q: Why is an IP rating important for electrical equipment?

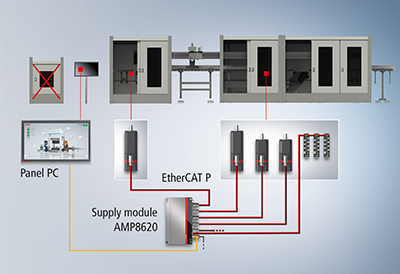

A: An IP rating is important when electrical equipment is deployed in dirty, dusty, wet, or other harsh conditions found in most industrial environments. The level of protection provides the user with an understanding of the equipment’s protective capabilities so they can work safely, with less risk of injury to themselves or damage to the equipment. Many industrial environments require that electrical equipment, and its sub-components, to have a rating of IP65 or higher. One such industry that requires an even more stringent rating is the food and beverage industry, which needs a rating of IP69K due to frequent washdown cycles to prevent the assortment of cleaners and water from affecting a machine’s electrical equipment.

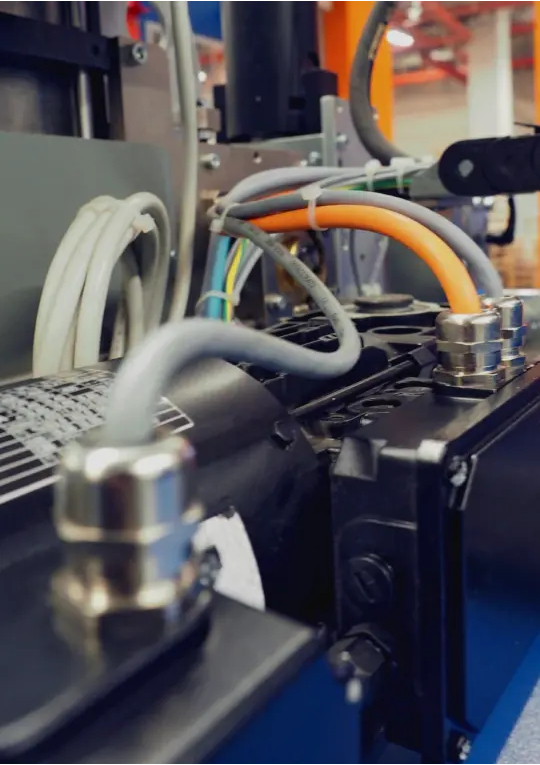

Q: How can a cable or wire help ensure an IP rating is met when used with a gland or connector?

A: Cables can help ensure the IP rating is met by being concentric, or uniformly round. If a cable is convoluted the gland or connector will not fit securely and there will be gaps between the cable’s jacket and the seal within the gland or connector that could allow water or other particles to pass through. In order to make a cable uniformly round quality manufacturers pay attention to designing the cable so that during the cabling or bunching process all components make the smallest overall diameter without compromising performance. Along with the conductor layout optional fillers such as jute, solid PVC or defibrillator polyethylene can be used to fill voids in the cabled conductors before the jacket is applied.

Q: Where do IP ratings apply when it comes to electrical equipment and who sets the standard?

A: Fittings that allow entry into an enclosure such as cable glands and conduit system components or connections to electrical enclosures by a connector – M8, M12, etc. – can be tested for an IP rating. We also see IP ratings assigned to luminaires located in industrial equipment. The ratings assigned have been tested to meet the requirements of the International Electrotechnical Commission (IEC) 60529, which defines the protection standards for mechanical casings and electrical enclosures. These standards include broad testing across a range of operating conditions to make sure electrical equipment functions safely and reliably.

Ingress Protection (IP) Rating Guide

Related Story

HELUKABEL Automotive Cables

At HELUKABEL, they understand that the automotive industry demands cables that are designed for high performance and reliability. That’s why their cables are engineered to withstand the tough conditions of the automotive environment, from extreme temperatures to harsh chemicals.