Danfoss Announced as A Member of the Ellen Macarthur Foundation’s Network, to Accelerate the Circular Economy Transition

March 24, 2023

Danfoss has been announced as a Member of the Ellen MacArthur Foundation’s Network, which will support the company’s circular economy journey.

The Ellen MacArthur Foundation is committed to the creation of a circular economy that tackles global challenges, such as climate change, biodiversity loss, waste, and pollution.

Danfoss has joined the Foundation’s Network as part of our efforts to support the transition towards a low-carbon and circular economy, and we will develop and implement a circularity framework in all our segments. Circularity is one of the key step-change initiatives of Danfoss’ ESG ambition, alongside Decarbonization and Diversity & Inclusion.

Martin Rossen, Senior Vice President, Head of Group Communication & Sustainability, Danfoss, says: “To be accepted as a Member of the Ellen MacArthur Foundation’s Network puts Danfoss alongside many of the world’s leading organizations whose circularity practices we can aspire to and learn from. Everyone claiming this is a walk in the park is lying – we need to help, inspire and support each other for the sake of our businesses and the climate. Don’t be mistaken. At the same time, we at Danfoss are very proud of our work on our Danfoss Circularity Framework and our goal is to integrate circularity assessments as part of all product development projects.”

Martin Rossen, Senior Vice President, Head of Group Communication & Sustainability

Danfoss Circular Economy Principles

The circular economy is based on three principles, all driven by design: eliminate waste and pollution, circulate products and materials, and regenerate nature. Danfoss’ circularity target for 2030 is that more than 80% of newly developed products sold will be covered by the circularity approach, and that circularity collaborations will be established with 80% of Danfoss’ top 25 customers.

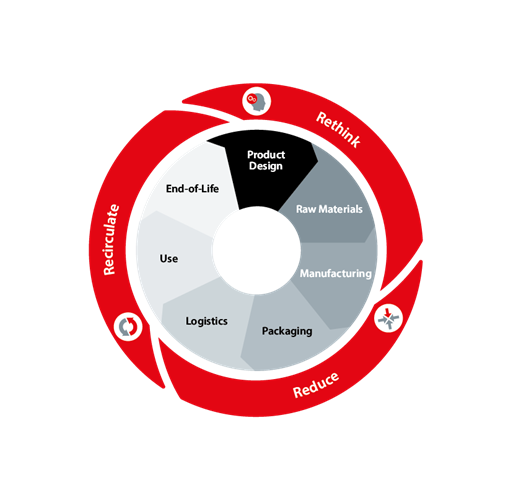

Danfoss’ Rethink-Reduce-Recirculate approach will drive the innovation and development of new products and is inspired by the approach developed by the CIRCit research project and five Nordic universities. In 2022, the Danfoss Circularity Framework was refined based on the Rethink-Reduce-Recirculate principles and incorporated nine circularity strategies that can be applied in new product development across Danfoss. The framework measures circularity when designing new products and identifies opportunities for improvement.

This year the circularity framework and an assessment tool will be implemented in several projects across Danfoss’ business segments.

“Our aim is to accelerate the development of low-carbon products and circularity initiatives across all our business segments, but it’s hard work and difficult. Our focus is on mechanical and electronics products and we are excited to further develop our approach to circularity and positively impact our product design strategy with this Network. The Ellen Macarthur Foundation includes some of the world’s largest and most influential organizations, with transformative potential to demonstrate what’s possible within circularity,” adds Martin Rossen.

Martin Rossen, Senior Vice President, Head of Group Communication & Sustainability

From the Ellen MacArthur Foundation

Katie Attrill, Network Manager, Ellen MacArthur Foundation, says: “We welcome Danfoss as a Network Member and look forward to supporting the company on its circular economy journey. We work with a group of more than 250 organizations as part of our formal Network. The Network includes some of the world’s leading businesses, policymakers, cities, academic institutions, and thought leaders. With our Network, we facilitate collaborative projects, provide learning opportunities and host workshops and other events to explore strategies and solutions that support their circular economy transition. “

Katie Attrill, Network Manager, Ellen MacArthur Foundation

Danfoss will continue its work with universities and other companies to ensure that the assessment tool and circularity framework adopted are validated and they capture circularity principles and concepts in an accurate and complete way.

Related Product

Danfoss Expands its Line of Reliable High-Quality Burner Components with new Bio100 pumps

Transitioning to liquid low-carbon fuels is an important part of the CO2 decarbonization journey. Many of these fuels, which are created from different types of raw materials, are already available and will contribute significantly to climate protection together with modern oil-fired condensing boilers.