Future-Poof Labelling! Safety That’s Customized, Adaptable and Instantly Usable

December 19, 2022

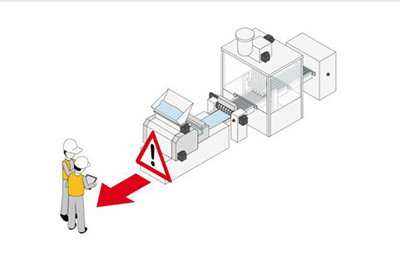

It was predictable that the planned integration of a new laser in the end-of-line packaging for the glass coffee jars at Haco would entail some risks, because the PNOZ X safety relay that had been used previously could not be adapted to the line’s increased requirements. An alternative expandable, modular solution was therefore to be used. An additional demand: as the plant is in operation almost round the clock, the downtime and associated loss of production was to remain as low as possible. With its new, simple configuration, order and commissioning mode, the modular safety relay myPNOZ offered Haco a rapid, customized safety solution, tailored to their individual requirements and operational almost from the start.

Risk-free filling – now and in the future

Today, operators on the filling plant’s turntable are not only protected from the hazards of the laser, but also from the drives’ hazardous overrun: the inputs of the dual-channel emergency stop and the OSSD signals of the safety gate systems PSENmlock are connected directly to each other on the myPNOZ, so creating a safety zone, which comprises both the actuator technology – including the powered turntable– and also the laser. The required functionality was entered and ordered via the myPNOZ Creator: five modules in total were required to safeguard the workstation at the turntable – the head module responsible for the safety circuit on the employed emergency stop pushbuttons, an additional input module for the safety gate systems and three output modules for the actuator technology. And – should the requirements on the filling line change in future – myPNOZ can be adapted flexibly at any time.

Benefits at a glance

- •Safety solution is operational almost from the start, meaning high productivity despite the conversion

- •Functionalities for the update of the filling line can be configured precisely via the online tool myPNOZ Creator

- •Modular safety solution with myPNOZ, which can be expanded and adapted at any time in the future

Customer statement

“The safety relay myPNOZ was exactly what we were looking for at that time – a suitable solution that could be integrated with practically no downtimes! myPNOZ opened up new opportunities for us to implement tailor-made solutions. The individual “pay-what-you-need” approach offers an optimum cost-benefit ratio.”

Piotr Grzelinski, Electrical Design Engineer at Haco AG

About Haco AG

Haco AG, based in the Swiss town of Gümligen, is part of Haco Holding AG, which employs around 1,600 staff. The Haco Group comprises eleven companies, with 14 sites in Europe, Asia and North America. Founded in 1922, it specializes in the production of custom food products, including convenience products such as soups, ready meals, cereal bars, instant drinks and coffee. Haco Holding AG carries out the majority of the plant maintenance, adjustments and optimizations itself, guided by creation, innovation and strong customer focus.

Modular Safety Relay myPNOZ

Easy-to-use, modular safety relay with an internal combination logic for monitoring emergency stop, safety light curtains or two-hand controls IIIA/C for example, in small to medium applications with 2 to 16 safe input functions

To learn more about the Modular Safety Relay myPNOZ, click here

Sensor Technology

The optimum solution for your application: Safety switches for monitoring positions and guards, optical sensors such as light barriers or camera systems for monitoring areas and zones.

To learn more about Sensor Technology, click here