Research from ABB Shows How Cities Can Tackle Water Stress by Reducing Carbon Emissions and Cost of Wastewater Treatment for Reuse

November 15, 2022

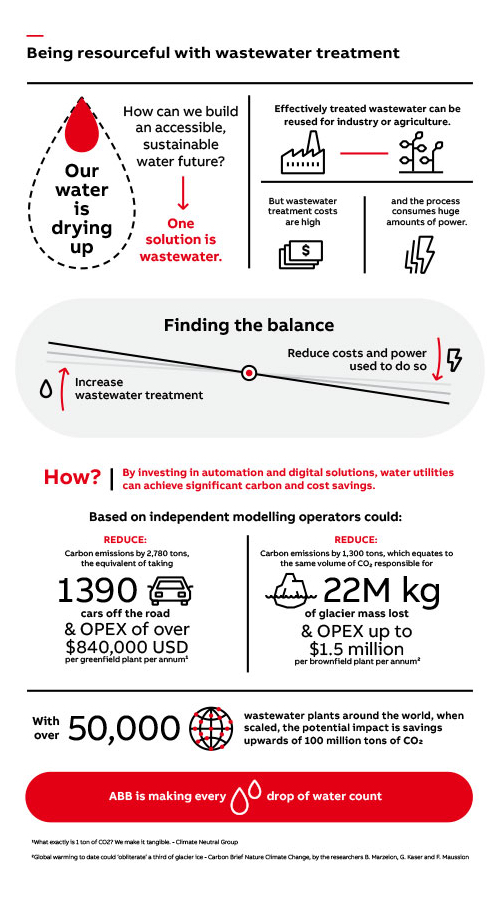

- •ABB’s “Energy Transition Equation” report demonstrates how automation and digital technology can help wastewater companies reduce carbon emissions by up to 2,000 tons per annum1 , the equivalent volume of CO2 responsible for 30,000 tons of glacier mass lost every year2

- •With over 50,000 existing wastewater plants worldwide and a predicted industry growth rate of over 7 percent, if scaled, the impact in tackling water scarcity and industrial carbon emissions, is vast

- •Average operational cost savings of up to $1.2 million per plant3 provides cities with an affordable pathway to treat more wastewater and reduce amout of untreated wastewater pumped into rivers and seas

Recently, ABB published the first in a series of new reports for the energy and wastewater sectors to highlight the impact that technology can have in enabling industrial customers to reduce carbon emissions and manage the energy transition for a more sustainable future.

With the United Nations predicting a 40 percent water deficit by 20404, ABB has conducted research to reveal how better use of wastewater could relieve pressure on water supplies.

When treated effectively, wastewater can be returned to the water cycle for reuse, proving a valuable but often untapped resource in tackling water scarcity. Importantly, it also lowers the levels of untreated sewage pumped into rivers and oceans, which have hugely negative impacts on public health, the environment and marine life.

“Global data shows that only half of our wastewater is properly treated5,” said Brandon Spencer, President, ABB Energy Industries. “Allowing untreated wastewater back into our water courses not only has a disastrous effect on fisheries, animals, marine biodiversity, and public health, but it is also a terrible ‘waste’ of this commodity. We need to be doing more.”

Treating wastewater, however, requires a lot of power, with the industry at large consuming up to three percent of the world’s total energy output6 and contributing over 1.5 percent to global greenhouse gas emissions.7

Seeking to redress this balance, ABB has conducted nine months of research and modelling with an independent economist, to demonstrate how greater adoption and integration of process automation technologies, can deliver both carbon and cost savings to enable more efficient treatment of wastewater.

The findings reveal that in wastewater sites, utilities could reduce carbon emissions by up to 2,000 tons per annum8, the equivalent volume of CO2 responsible for 30,000 tons of glacier mass lost every year. With over 50,000 existing wastewater plants worldwide, the opportunity, if scaled, is upwards of 100 million tons of CO2 saved.9

Furthermore, in applying a robust package of process control and digital solutions, water companies could reap annual operational savings of up to $1.2 million (9.5 percent) per plant, opening revenue streams to ensure higher volumes of wastewater are treated and less is discarded in our rivers and seas.

“ABB is committed to leading with technology to preserve precious resources such as water and energy, and ultimately enable a low-carbon society and a more sustainable world. In 2021, we have reduced our own CO2 emissions by 39% percent, compared with the baseline year of 2019, and as part of our Sustainability Strategy 2030, we are working with our customers with the aim of reducing their annual CO2 emissions by at least 100 megatons by 2030,” said Brandon Spencer.

The global wastewater market, driven by the need for more freshwater, population increase, and stringent environmental regulations, is projected to grow from $300 billion in 2022 to $490 billion by 2029.10

The reports’ economic modelling was undertaken by independent economist Steve Lucas of Developmental Economics11 in conjunction with ABB Energy Industries and supported with desktop research of academic and industry sources. ABB will publish further economic reports focused on the offshore, power and chemicals markets across 2022 and 2023.

To read and download the report, click here: solutions.abb/energy-transition

Notes:

Some research figures have been rounded out for the purpose of the press release – exact calculations and figures can be found in the report. Full breakdown of calculations included can be downloaded here

These figures are based on 1 x 95 ML greenfield wastewater facility with an operational life cycle of 32 years (and development phase of 4 years), and 1 X 50ML brownfield wastewater facility with an extended operational life cycle of 32 years.

1. Average figures taken across findings for new (greenfield) and existing (brownfield) wastewater facilities.

2. Source: Global warming to date could ‘obliterate’ a third of glacier ice – Carbon Brief, Nature Climate Change, by the researchers B. Marzeion, G. Kaser and F. Maussion

3. Average figures taken across findings for new and existing wastewater facilities

4. https://unesdoc.unesco.org/ark:/48223/pf0000231823_eng

5. ESSD – Country-level and gridded estimates of wastewater production, collection, treatment and reuse (copernicus.org)

6. Circular Economy: Tapping the Power of Wastewater – International Water Association (iwa-network.org)

7. Wastewater treatment for carbon capture and utilization | Nature Sustainability

8. Average figures taken across findings for new (greenfield) and existing (brownfield) wastewater facilities.

9. https://www.waternewseurope.com/global-database-of-wwtps-and-their-effluents/#:~:text=More%20than%2058%2C000%20wastewater%20treatment,the%20wastewater%20treatment%20plants%20drain

10. https://www.fortunebusinessinsights.com/water-and-wastewater-treatment-market-102632

11. https://developmenteconomics.co.uk