ABB And Hydrogen Optimized Expand Hydrogen Partnership, Including A Strategic Investment

September 7, 2022

- •Collaboration positions companies for global leadership in large-scale green hydrogen production systems

- •Combined technological offerings will include Hydrogen Optimized’s RuggedCell™ high-power water electrolyzers and ABB’s high-power rectifiers

- •The two companies consolidated their alliance with a new commercial agreement signed at a hydrogen trade show in Stephenville, Newfoundland, attended by Canadian Prime Minister Justin Trudeau and German Chancellor Olaf Scholz

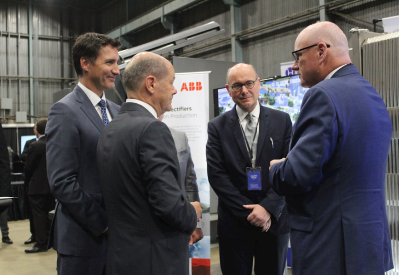

Canadian Prime Minister Justin Trudeau and German Chancellor Olaf Scholz discuss the importance of green hydrogen production to the two countries’ economic and energy futures. In turn, ABB Process Industries President Joachim Braun and Hydrogen Optimized CEO Andrew Stuart explain how ABB high-powered rectifiers support Hydrogen Optimized’s RuggedCell technology in using wind power to produce hydrogen at scale. The leaders met at the German-Canadian Atlantic Renewable Hydrogen Expo in Stephenville, Newfoundland Aug. 23

ABB and Hydrogen Optimized Inc. (HOI), the Canadian technology innovator unlocking green hydrogen production at scale, have signed an agreement to expand the companies’ existing strategic relationship. This includes an investment by ABB into Key DH Technologies Inc. (KEY), the parent company of HOI, as they seek to accelerate the fast-emerging green hydrogen production segment with unique large-scale architecture. The financial terms of the agreement were not disclosed.

The signing follows the two companies’ showcase of their green hydrogen technologies at the August 23, 2022 German-Canadian Atlantic Renewable Hydrogen Expo in Stephenville, Newfoundland, which was attended by Canadian Prime Minister Justin Trudeau and German Chancellor Olaf Scholz. Hydrogen produced with low-to-zero carbon dioxide emissions is widely recognized as essential to achieving net-zero emissions by 2050..

By accelerating the strategic collaboration between ABB and HOI launched in 2020, the two companies are advancing the deployment of economic large-scale green hydrogen production systems to decarbonize hard-to-abate industries that address a wide range of essential needs – energy, metals, cement, utilities, ammonia, fertilizers, and fuels for aircraft, ships, trucks and rail.

The companies will leverage their respective capabilities and resources to rapidly commercialize HOI’s patented RuggedCell™ high-power water electrolysis technology for the world’s largest green hydrogen plants. Water electrolysis is the process of applying electrical energy to split water into hydrogen and oxygen. RuggedCell™ technology converts renewable electricity such as hydro, solar and wind power into green hydrogen for industry.

“We look forward to building on our companies’ two-year working relationship to pursue the enormous global opportunity of green hydrogen,” said Joachim Braun, Division President, ABB Process Industries. “Following a rigorous validation of the RuggedCell™ technology, we are confident that, in combination with ABB’s high-power rectifiers, it can become a category leader in the large-scale green hydrogen segment. Our complementary technologies will strengthen the Hydrogen Optimized value proposition and fast-track the commercialization of the RuggedCell™.”

“This agreement positions us for success in the large-scale segment with customers requiring installations in the hundreds of megawatts to multi-gigawatts,” said Andrew T. B. Stuart, President and CEO of KEY and HOI. “ABB’s global footprint, commercial relationships and technology leadership in high-power rectifiers, distributed control systems and manufacturing automation provide us with the market reach and capabilities to achieve our company’s goals.”

Global electrolyzer capacity will reach an estimated 3,100 gigawatts by 2050, according to a June 2022 report published by DNV. The group forecasts that electricity-based green hydrogen will be the dominant form of hydrogen production by the middle of this century, accounting for 72 percent of output.

The proceeds of ABB’s investment into KEY, led by ABB Technology Ventures (ATV), will be used to advance HOI’s intellectual property development, build up corporate capabilities for increased business activity and introduce automated manufacturing and robotics. This will accelerate the rollout of gigawatt-scale electrolyzer manufacturing.