Safety for Press, Human and Robot! International Application by PILZ

July 25, 2022

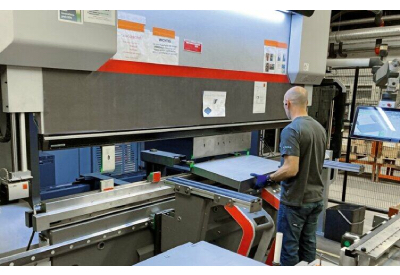

When the Swiss engineering company Peter Huber AG won the order to upgrade and convert the control and safety technology on manual-feed bending machines – to include an additional sheet metal feed via robot – alongside the requirements for economy, flexibility and efficiency there was also one key condition in the requirement specification: wherever possible, the envisaged solution should continue to use the existing controllers.

As cooperation between human, robot and machine presents a complex challenge not only in control terms but also regarding safety, an innovative solution was sought. Peter Huber found it in the modular safety relay myPNOZ.

Interface with safety guarantee

The particular focus of the safety concept: the new interface between the robot and bending machine, as this poses a variety of risks for the people located there. Firstly, no operator should stand too close while the robot is loading; secondly, the safety concept must guarantee that operator and in particular finger protection is fully reliable when inserting, or when correcting a position by hand. And: the safety device or measure must not hinder the operators as they go about their activities.

As both the bending machine and operating robot already had their own separate machine and safety controllers, this project required an integrated and efficient safety solution for this interface. Due to the extensive modularity and therefore flexibility of the myPNOZ, it was possible to achieve the specification of retaining the controller environment, while increasing the productivity and flexibility of the bending machine.

Benefits at a glance

- •Simple retrofit: existing safety controllers can continue to be used

- •No need to develop a completely new safety solution because myPNOZ is an interface that can be integrated between the robot and bending machine

- •Flexibility: application can be quickly adapted to new jobs, if necessary

Customer statement

“In the concept design phase, the technical support team at Pilz drew our attention to the modular safety relay myPNOZ, which had just been launched on the market: the idea of expandable input circuits with just one safety relay impressed us right away. The fact that we can tailor the device one hundred per cent to our requirement and then have it delivered ready to install brought us all sorts of benefits in terms of time and costs.”

Erich Schuhmacher, Project Manager and expert in conveyor technology, handling and robotics at Peter Huber AG

About Peter Huber AG

For more than 40 years the automation service provider Peter Huber AG, based in the Swiss town of Alpnach, has used its considerable expertise and experience to turn complex customer requirements – covering controllers, robotics, handling systems, data and control station systems, retrofits and optimisations – into successful and economical solutions that have proven their worth in practice. The innovative engineering company Peter Huber AG accompanies its customers from design through to final commissioning.

PILZ’s product in the application

Easy-to-use, modular safety relay with an internal combination logic for monitoring emergency stop, safety light curtains or two-hand controls IIIA/C for example, in small to medium applications with 2 to 16 safe input functions.