Endress+Hauser Extending Pioneering 0 X DN Full Bore Option to More, Tougher Applications

March 14, 2022

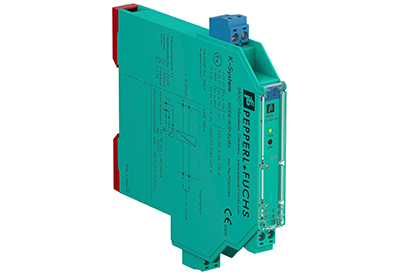

Endress+Hauser is extending its world-first 0 x DN full bore option to more flow measuring applications, including tough ones with line sizes 25mm to 2400mm (1” to 96”). This option was launched initially for Promag W electromagnetic sensors for water/wastewater applications, but now also can be ordered with Promag P sensors in chemical and process applications with corrosive liquids or the highest medium temperatures. Furthermore, the 0 x DN full bore option now is compatible with the new Promag 10 transmitter, with its new design, Bluetooth connectivity and touchscreen controls, as well as with the well-established Promag 300/400/500 series transmitters.

(Endress+Hauser is showcasing its advanced flowmeters and other liquid measurement and analysis solutions at the Alberta Water and Wastewater Operators Association’s 47th Annual Operators Seminar, March 14-18 in Banff.)

For operators, Endress+Hauser’s electromagnetic flowmeters with the 0 x DN full bore option offer much greater flexibility in designing or upgrading process systems. The full bore option delivers excellent measurement accuracy without any measuring tube restriction – irrespective of the flow profile or mounting location. That makes flowmeters with this option ideal for installation in tight spaces, such as compact systems or skids, because they do not need any inlet or outlet runs.

Otherwise, plant operators usually have to compensate for flow disturbances by adopting the recommended inlet and outlet runs or by employing a flow measuring device with a restricted measuring tube. However, sufficiently long straight pipe sections may not be not available for the former, while tube restrictions cause pressure loss that often leads to increased energy consumption for pump operations and higher energy costs.

Endress+Hauser flowmeters with the full bore option feature multiple measuring electrodes to detect abnormalities in the flow that can impact measurement accuracy. This generates a substantially higher density of measured data than for standard devices. Measurements aren’t distorted by frequently occurring swirls caused by influences such as a close-knit pipeline network or obstacles in the pipe like pipe bends and insertion devices or build-up on the pipe wall, protruding seals or different interior diameters.

Endress+Hauser Promag W and P sensors all meet IP67/NEMA6 rating for permanent submergence or temporary submergence for up to 10 days.

For more information, visit HERE.