Ethernet-APL Simply Explained—How Parallel Communications Work

December 8, 2021

Ethernet Advanced Physical Layer, Ethernet-APL for short, is the physical layer for transmitting data into the field of process plants. Pepperl+Fuchs explain in simple and understandable language what exactly Ethernet-APL is, how parallel communication works today and what possible options there are to access data.

What is Ethernet-APL?

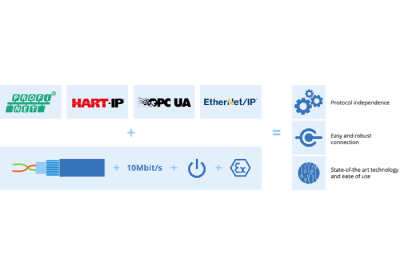

Ethernet-based protocols such as EtherNet/IP, HART-IP, OPC UA or PROFINET utilize different physical layers. This can be explained with the ISO/OSI model (Fig.1), which generically describes communication across different systems.

For wire-based communication, the physical layer, which is layer 1, defines the electrical system: cables and connectors, signal levels, power supply, and electrical explosion protection.

Layer 7 defines how bits and bytes represent data, e.g., an analog measurement value, a counter, or a digital control output. In the context of industrial protocols, technicians and engineers however often consider a protocol like FOUNDATION Fieldbus H1 or PROFIBUS PA as one function unit. For Ethernet-based protocols, we need to abandon this simplified view. Ethernet protocols run on various media. They communicate with 10 Mbit/s, 100 Mbit/s, or 1 Gbit/s speeds. They utilize fiber optics or even Wi-Fi (blue boxes in layer 1), and finally Ethernet-APL. This physical layer is fit for the rough or at least very demanding environment in the field of process plants (green box in layer 1).

What Does Parallel Communications via Ethernet Mean?

Very simple—just think about your daily life. Where are you working? From home, on the road, or in your office? Parallel communication is the standard way of life: You might be on the phone, writing an e-mail and browsing on a website on your laptop, and all at the same time. Your children may be attending school classes or playing online video games on tablets in their rooms. And the same happens in the neighbors’ houses. This is parallel communication carried via Ethernet and other physical layers such as cable or DSL.

Or consider the following analogy: Ethernet is the road, the protocols are car brands, e.g., PROFINET, OPC UA, EtherNet/IP, HTTPS, SIP, and VoIP. The road carries any vehicle. Multiple cars and trucks can ride on the same road, until there is so much traffic that there is a traffic jam. This is where network architects come into play: they take care of the appropriate design so that traffic can run properly without congestion. Basically, Pepperl+Fuchs builds the road with switches and junction boxes, and does road maintenance with physical layer diagnostics.

For the field of process automation parallel communication means that multiple systems can access data stored in the instruments simultaneously. It can be expected that planners will select the following:

- One real-time enabled protocol for control. This choice depends on the selected control system or PLC. NAMUR recommends PROFINET or EtherNet/IP.

- One or more protocols for other applications such as processing diagnostic messages, alarms, or configuration management.

NAMUR recommends OPC UA. Many vendors, Pepperl+Fuchs alike, implement this protocol in their instruments.

HART-IP: This is what we offer with Pepperl+Fuchs Remote I/O today.

HTTPS: Surf to the instrument from your smart phone or PC. All vendors do that in their demos today.

Multiple Ways to Access Data from the Instrument

When you direct your web browser to any website, the web browser is your client and connects to the server of the website owner. With Ethernet-APL you can call the webpage of the field instrument. The device itself then hosts the HTTPS server that you interact with: you can access status and alarms, view manuals or certificates. This happens in parallel to access from the DCS or the asset management system.

Field instruments with Ethernet-APL can host these functions, depending on the vendor’s implementation of the device. Ethernet-APL opens possibilities for parallel access enabling applications that enrich and enhance the work lives of everyone working with instrumentation and automation. This will enable users to optimize their plant for the benefit of worker safety, utilization of their plant assets, output quality and yield.