ADVANCED Motion Controls Releases 60Amp Micro-Sized FlexPro Servo Drives

November 23, 2021

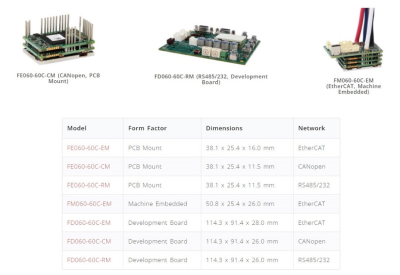

ADVANCED Motion Controls has released 7 new micro-sized FlexPro servo drives rated to output 60A continuous. The 60A continuous current rating is 33% higher than previous models for the same size making these our highest power-density servo drives to date. This offering includes PCB Mount, Machine Embedded and Development Board form factors.

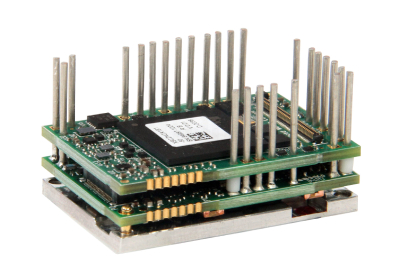

PCB Mount Form Factor

With a footprint of 38.1mm x 25.4mm, up to 4 FlexPro servo drives can fit within the area of a standard business card. The PCB Mount form factor is our most compact configuration with no connectors or housing. They’re intended to be soldered directly to a PCB to help achieve the highest levels of integration.

Machine Embedded Form Factor

These models add a compact interface card to the PCB Mount versions to allow for direct connections with power and signal wires. This form factor makes it easy to install servo drives just about anywhere in a machine.

Development Board Form Factor

Essentially the same as the other models in this product launch but mounted to a larger board populated with full-sized connectors with more spacing in between. Development boards are great for proof-of-concept designs and for setting up experiments on a bench top.

Features:

- EtherCAT, CANopen, RS485/RS232 communication available

- 10-55 VDC input voltage

- Rated for 60A continuous current

- Incremental encoder, EnDat 2.2, and BISS C-mode feedback

- Torque, velocity, and position operating modes

- Configuration and full loop tuning

- STO (Safe Torque Off)

- IMPACT™ architecture

Projected Industries & Applications:

The small size of the FlexPro® drives makes them perfect for cobots (collaborative robots), AMRs, AGVs, portable devices, lab and warehouse automation, military equipment, and any other integrated design.

About IMPACT™

IMPACT™ (Integrated Motion Platform and Control Technology) is the architecture that makes AMC’s FlexPro® drives possible. The stacking of circuit boards with creative selection and placement of high-power components allows for much higher power density than previously produced servo drives. The expanded processing capabilities ensure the drive’s intelligence is unmatched. IMPACT™ made its debut with FlexPro®. This technology will be used in subsequent FlexPro® drives as well as any future custom products where it is desired.

The full selection of 60Amp FlexPro drives can be found here.

For further information, visit Electromate by clicking here