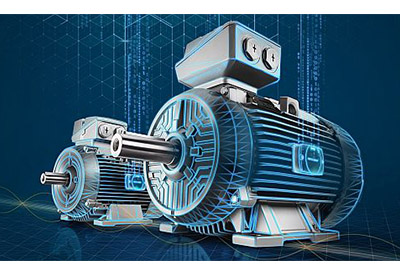

Siemens: Digitalize Your Low-Voltage Motor With SIMOTICS CONNECT 400 and SIDRIVE IQ Fleet

October 28, 2021

Interested in getting a quick and comprehensive overview on the condition and operational state of the low-voltage motors driving your applications such as pumps, fans, or compressors? With the plug-&-play connectivity module SIMOTICS CONNECT 400 and MindSphere analytics app SIDRIVE IQ Fleet, you can easily implement a cost-effective, cloud-based solution for continuous, LV motor condition monitoring – worldwide and 24/7. Whether to monitor new motors or flexibly upgrade your installed base, SIDRIVE IQ Fleet improves LV motor reliability, availability, efficiency, performance, and productivity.

Use cases for operators

Prolong product life

Based on the operational data and the actual condition state of the motor, SIDRIVE IQ Fleet defines the optimum maintenance levels, prolonging product life by up to 30%, saving resources and increasing plant availability.

Increase productivity

By continuously monitoring and analyzing the operation of your applications, maintenance cost can be reduced by up to 30%. In combination with the reduction of downtimes and breakdowns, plant productivity can be increased by 8% to 12%.

Save energy and make a good impact on the environment

By using artificial intelligence (AI) and data analytics, digital motors identify inefficiencies in complex processes. Optimizing those processes can lower energy consumption and CO2 emissions by up to 10%. This not only saves costs but also reduces your environmental footprint and increases your impact on our environment.

Use cases for service providers

Earn money with digital, service-focused business models

Service providers are able to offer profitable maintenance and service business to a complete new extend by utilizing:

- – the plug-and-play design of our system

- – the powerful analytics and

- – the easy data sharing capabilities of Siemens’ solution.

You will not only earn money, but also improve the relationship to your customers by knowing exactly what they need.

Save time and cost with remote services

By precisely knowing the condition state of your customer’s applications and the capability of analyzing the latest developments, service providers are able to support operators quickly from remote. That reduces and avoids possible outages for your customer and saves time and money for you.

Optimize serviceability

Improve the way how you offer services by utilizing the benefits of remote monitoring and cloud-based fleet management. Increase your efficiency by optimizing service planning and execution processes and therefore increase your overall service capacity by changing from a time-based to a condition-based maintenance approach.

Use cases for OEMs

Offer digital products and profitable services around it

Offering digitally connectable and intelligent products is not only the foundation for Industry 4.0, but also a big opportunity for innovation and differentiation from competitors.

The connectivity can either be part of a standard product offering or easily retrofitted on the installed base. In addition, digitally enhanced products enable profitable service business which will play a big role in future business plans.

Enhance your analytics by integrating motor data via API

With our powerful API, you are able to enrich your applicational knowhow with our domain expertise on drive technology. Pull operational data, status KPIs and notifications from SIDRIVE IQ Fleet into your application to further increase the value you create for your customers.

Optimize serviceability and handling of warranty cases

Use the operational transparency to optimize the handling of warranty cases and therefore, reduce costs. With the help of connected products and remote monitoring, you can increase your efficiency by optimizing service planning and execution processes and therefore increase your overall service capacity.