Using Variable Speed Drives to Reduce the Risk of Pump Cavitation

September 27, 2021

Cavitation can be a serious issue for industry. It causes damage to pumping systems, reducing their lifetime and requiring costly maintenance and replacement, while in the beverage and dairy industry it can impact the quality of products being pumped. This article outlines the causes of cavitation and explains how the latest variable speed drives (VSDs) offer an efficient and cost-effective method to prevent it.

Cavitation can occur in many different pumping applications, but it is a particular challenge for the water and wastewater industry where a high number of large pumps are deployed. The result is an increased risk of downtime and higher maintenance costs. The issue goes beyond the need to replace a damaged pump. In remote areas in particular, the cost of sending a maintenance team with heavy lifting equipment to the site might be many times the cost of the pump itself.

The risk of pump damage is also important for the beverage and dairy industry. However, there is an additional risk of cavitation leading to the formation of bubbles or foam when pumping fluids such as milk, soft drinks or beer. In the dairy industry in particular, cavitation can damage the milk-fat globules. Or a batch of beer that has taken weeks to brew might foam to the point where it has to be discarded.

Cavitation can happen when the pumping process subjects a liquid to rapid local changes in pressure, creating vapor-filled bubbles. The exact point at which this liquid-to-vapor transition occurs depends on the pressure. It is well known that water will transition into steam at 100°C – its boiling point at normal atmospheric pressure. When the pressure in the system is reduced this occurs at lower temperatures. Eventually, when the pressure is reduced to a vacuum, the transition happens at room temperature.

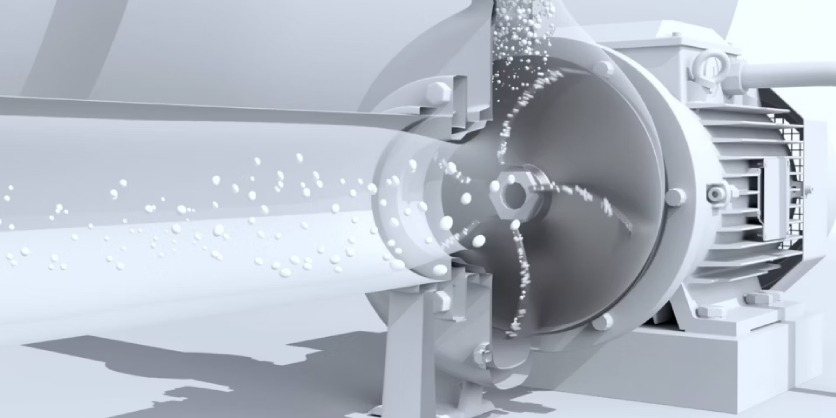

When the impeller is spinning in an industrial centrifugal pump, high pressure is created on the front side of the blades. Simultaneously, there is low pressure on the back of the blades. In some conditions the water will vaporize, creating bubbles – see Figure 1. When these vapor bubbles reach areas of high pressure, they implode, collapsing back into liquid form and producing significant shockwaves. The rapid implosions generate a characteristic rumbling or cracking noise associated with cavitation, sounding like rocks passing through the pump.

Each implosion causes only a tiny shockwave. However, because they occur in large numbers, the cumulative effect impacts pump performance. Eventually, cavitation damages the pump impeller, housing and other components in the pumping system through wear and metal fatigue. It is common for cavitation to shorten the life of a pump by as much as half. In the very worst cases, pumps have been destroyed in a matter of minutes.

Open systems are most at risk

Closed pumping systems circulate water in closed loops, typically for heating or cooling control. Their pre-pressurized setup generally prevents cavitation during operation, unless there is leakage.

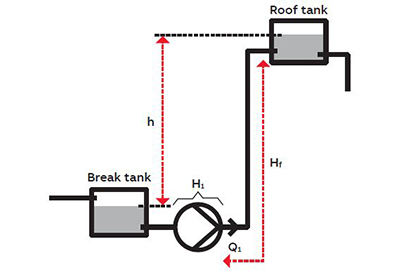

In contrast, open pumping systems, such as for drinking water distribution or wastewater treatment, are subject to cavitation should the inlet pressure drop below the Net Pressure Suction Head (NPSH) – see Figure 3. NPSH, quoted in meters or feet, is a measure of the pressure experienced by a fluid on the suction side of a centrifugal pump. It is volume dependent and given by the pump manufacturer as a specific value for each pump.

The inlet pressure to the pump will decrease as the level in the break tank decreases. This could lead to a situation where the inlet pressure drops below NPSH for the specific pump, resulting in cavitation. There is generally no risk of cavitation if the inlet pressure stays above the NPSH requirement.

Preventing cavitation

The first step to avoiding cavitation is to pay attention to the design of the pumping system. One vital measure is ensuring that the available NPSH exceeds the required NPSH. This can be achieved by decreasing the number of elbows and valves in the inlet pipework, shortening the length of the pipework, or increasing its diameter. Reducing the temperature of the fluid or pump can also help This isn’t practical in the water industry but might be possible when pumping beverages.

When working with existing systems, or where space is at a premium, it can be difficult to implement the optimum design. In which case, the answer is to consider how best to detect the onset of cavitation and modify the pump operation accordingly.

It can be possible to use discrete sensors, such as differential pressure transducers, to monitor the changes in pressure that accompany cavitation. However, it is more cost-effective to use the extended capabilities of the new generation of intelligent variable speed drives (VSDs) – also known as variable frequency drives (VFDs) – already used in many industrial pumping applications.

In addition to the benefits of energy efficiency and a variety of useful functions, such as pump cleaning to avoid blockages, some VSDs, including ABB’s ACS880 range, now incorporate anti-cavitation software. This makes it possible to prevent cavitation without the additional cost and complexity of external sensors and PLCs.

How does an intelligent VSD prevent cavitation?

The dedicated anti-cavitation software built into a VSD uses algorithms to measure pump torque and speed. It checks for the specific patterns that indicate cavitation is taking place. Since the measurements are taken directly from the pump shaft there is no latency in detection, so the response is virtually instantaneous. When it detects cavitation, the VSD adjusts the pump speed automatically to react to the change in pressure. It will resume normal operation as soon as the pump has stopped cavitating.

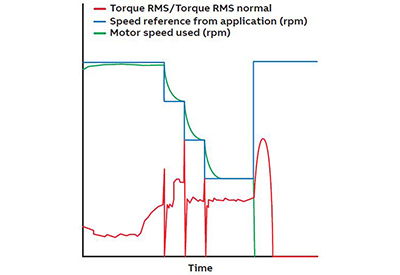

Figure 4 shows the operating principle behind the anti-cavitation algorithm.

The VSD algorithm detects the onset of cavitation by comparing the torque measured on the pump shaft against the nominal torque. If cavitation starts, then the torque curve, shown in red, starts to rise.

The software responds by adjusting the speed reference, shown in blue, to a lower level. This results in a reduction in the actual motor speed, as shown in green. The algorithm can be adjusted to suit different operating conditions. In many cases, the VSD will be set up to stop the motor running if cavitation still continues for longer than a set time after the motor speed has been stepped down. In other applications it might be desirable to stop the motor as soon as cavitation is detected.

VSDs drive away the risk of pump cavitation

Pump cavitation is a significant risk for industry. If it is not tackled, it can cause significant damage and disruption to pumping operations as well as impacting product quality.

The new generation of intelligent VSDs now make it possible to solve cavitation locally, within the drive, in real time. Because the anti-cavitation software is built into the drive, no extra components such as sensors or PLCs needed. The only additional installation effort required is to set the operating parameters.

More Information

For further information, visit: https://new.abb.com/drives/low-voltage-ac/industrial-drives