Fluke Process Instruments MP Linescanner Series Speeds Non-Contact Temperature Imaging and Analysis

May 3, 2021

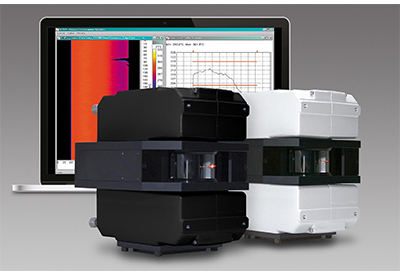

Fluke Process Instruments, a global provider of infrared temperature measurement and thermal profiling solutions for industrial applications, recently introduced the MP Linescanner Series, which delivers continuous, accurate, edge-to-edge thermal images and temperature measurements for high-speed manufacturing processes. The new imagers deliver real-time imaging at scans speeds up to 300 Hz and feature Fluke’s widest selection of spectral and temperature ranges to accommodate a variety of industrial applications.

“Scan rate is essential for rapid detection of temperature abnormalities, such as non-uniformities and hot spots,” said Dr. Martin Budweg, Global Product Manager, Fluke Product Instruments. “The new MP Linescanners can measure up to 1024 temperature points across a scan line at a rate of up to 300 lines per second, allowing manufacturers to better control their continuous moving processes, automate temperature measurements, and ensure product quality.”

The versatile MP Linescanner Series features rotating optics and a 90-degree field of view that quickly renders a 2D image on a PC. Additional key features include:

- – High-quality brushless motor (MTBF 40,000 h)

- – Built-in Ethernet TCP/IP communications

- – PC independent alarm output

- – PC independent 4-20 mA interfaces (3 outputs)

- – I/O module support for up to 10 sectors/zones (PC independent)

- – Internal Line Laser for accurate alignment

- – Rugged, waterproof IP65 enclosure

- – Air purge to keep the window free of dirt and condensation

- – Built-in water cooling for ambient up to 180 °C (356 °F)

DataTemp DP Software provides real-time monitoring and remote configurations

The MP Linescanner Series can be used in standalone mode, connected to a single PC, or integrated into a comprehensive process control system by using the DataTemp DP Software. This industrial Windows-based software package provides remote configurations of the imager and real-time process monitoring. The DataTemp DP Software supports multiple product-specific configurations (recipes), text file alarm logging and fail-safe alarm logging, and features the ability to support multiple linescanners, and real-time ambient temperature compensation/emissivity adjustments.

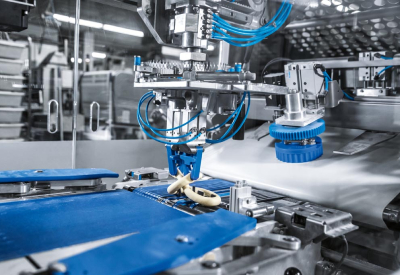

Fluke Process Instruments offers numerous customized process imaging systems to meet the specific application requirements for processes like glass processing, extrusion coating, thermoforming machine control, kiln shell monitoring, and gypsum wallboard production. Each customized system features application-specific software to help ensure product quality, quality improvements, reduced rework rates and more.