A Renewed Sense of Control in Canada – The Shift Towards Automation and Digitalization

April 20, 2021

As the mining business adapts to changing technological trends in the market, Epiroc’s Canadian operations have introduced Regional Application Center (RAC) teams to assist in this new digital transformation.

Team of experts that supports digital transformation

Across the board, mining projects are continually pushing for increased production while prioritizing safety. With this in mind, Epiroc has assembled specialized automation and digitalization support systems in strategic locations across the globe to help improve customer processes and boost productivity. The result is a heightened level of production that keeps workers out of danger zones on site while providing enhanced strategic direction for customers. Interoperability improvements have reduced variability and allow project planners to move towards their targets with renewed confidence.

“Our RAC team gives new perspectives on achieving efficiency for the organizations we partner with,” says Martin Champagne, Application Center Manager at Epiroc Canada. “The team itself utilizes members from a wide range of disciplines; from data analysts and project engineers to network specialists, software developers, IT specialists and digital product managers – the support system is always available when customers need it.”

6th Sense solutions

Epiroc’s Canadian Customer Center has successfully applied this technology since the late 90s, when the RCS Rocket Boomers with advanced boom controls and autodrill features were first introduced. In 2005, Canadian operations implemented one of the first Epiroc Scooptram Radio Remote Controls utilizing long-range Bluetooth technology; 2009 for the first fleet of semi-autonomous Epiroc Scooptram implementations; 2012 for the first fleet of Pit Viper 235s with tele-remote systems and 2019 for the first SmartROC D65 autonomous drill.

With Epiroc’s 6th Sense offering, the shift towards automation, digitalization and interoperability is already underway and the Regional Application Centers work collaboratively with many industry partners across the globe to achieve their goals. While working together with customers, Epiroc has initiated the move from machine autonomy to process autonomy, which consists of automating a complete process and allowing different kinds of equipment to communicate with each other effectively.

Smart support from the Control Tower

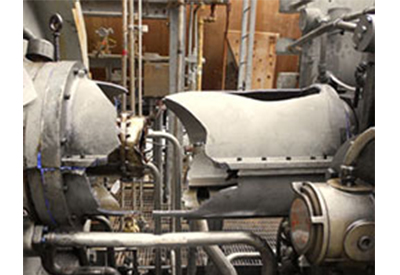

To help support these functions, a newly renovated Control Tower located at Epiroc’s Lively facility now acts as a home base for the RAC team, who are continually collecting data and developing innovative techniques to improve performance. Customers utilizing this service for their projects can now turn their focus to other areas of the business with the knowledge that Epiroc’s team of experts are carefully monitoring progress on site and offering solutions in real time.