New Module for Bending Angle Measurement on the Camera-Based Protection System PSENvip 2 From Pilz – Making Bending Processes More Productive

April 7, 2021

A new module for bending angle measurement is now available for the camera-based protection system PSENvip 2 from Pilz, which forwards usable image data to the press controller. So the operator sees the bending angle value directly on the user interface (HMI) when press braking, removing the need for expensive angle measurement systems and complex manual measurements. So the time and costs involved in the initial and subsequent adjustment of the system are reduced to a minimum. The bending process can be implemented productively and safely with PSENvip 2, thereby guaranteeing high availability on press brakes.

Over and above the time and cost savings, users also save space that would otherwise be needed to install additional devices.

Innovative technology even for rugged applications

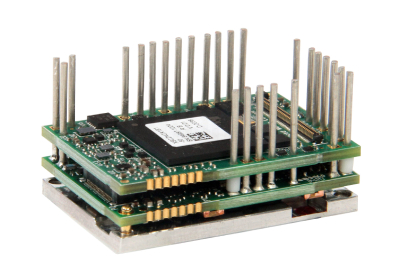

The camera-based protection system PSENvip 2 from Pilz monitors the whole bending process using innovative optics. When installed on the upper die of the press brake, the PSENvip 2 detects even the smallest foreign body in the protected field between the transmitter and receiver, enabling productive work practices in complete safety. Instead of a laser light source, PSENvip 2 uses an LED-based solution, in which simple illumination of the receiver along the upper tool is sufficient. Even under rugged application conditions, with vibration, reflection and external or diffused light for example, the protection system guarantees very high availability.

All-round package for safe press braking

The camera-based protection system PSENvip 2 offers maximum safety for press brakes as a complete solution with the Fast Control Unit in the automation system PSS 4000 in accordance with EN ISO 12622. The complete solution guarantees faster processing, so a shorter overrun distance and therefore an even faster shutdown of the bending processes. Maximum productivity and simple handling make for an efficient bending process.