Introducing the BradyJet J1000 Industrial Printer for Terminal Block and Control Panel Identification

November 5, 2020

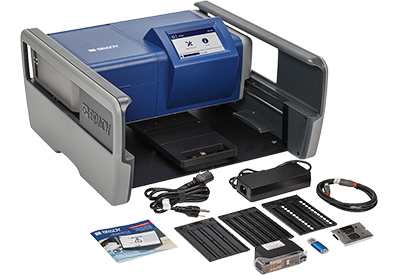

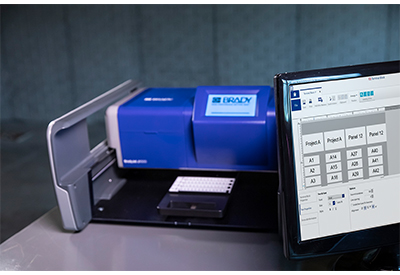

Customers who mark terminal blocks and control panel components know the process is intricate. But it can become more streamlined when all equipment, data and labels are connected and work together. With the new BradyJet J1000 Industrial Printer, Brady Workstation software and Brady materials, customers can experience just that. It’s an easy-to-use system that’s a model of efficiency.

One system – the BradyJet J1000 printer and Brady Workstation software can manage all terminal block ID tasks

Ease of use – imports data, allows tag creation and prints terminal block and component tags

Less waste – new inkjet technology means ink sets within seconds and allows partial tags to be reused

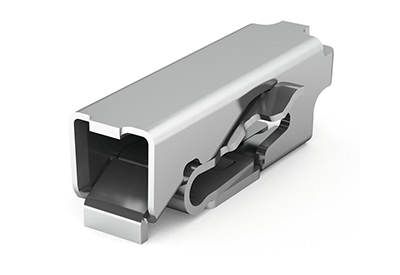

Compatibility – allows look-up of more than 1,400 terminal block makes and models

Reliability – uses one disposable ink cartridge with a fully integrated printhead

For more information, visit www.BradyCanada.ca/label-printers/J1000.