Yaskawa and Phoenix Contact Announce Partnership

September 14, 2020

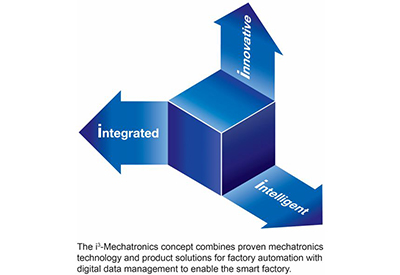

Yaskawa, a manufacturer of motion control, robotics, and variable speed drives and Phoenix Contact, a manufacturer of automation solutions are proud to announce an agreement to utilize PLCnext Technology from Phoenix Contact in the development of the next generation machine controller and PLC platform realizing the i3-Mechatronics solution concept lead by Yaskawa.

The common goal of both companies is to offer an open and future-proof ecosystem for industrial automation. In this context, Phoenix Contact has licensed its PLCnext runtime environment to Yaskawa and agrees on further joint developments.

Yaskawa sees PLCnext as the most open industrial automation software platform available today, combining IEC61131-3 programming, modern programming languages, safety hardware and software and control system security. It will use the PLCnext technology to further enhance and develop its machine control product offering.

PLCnext Technology is the open ecosystem for industrial automation from Phoenix Contact. With the combination of open control technology, modular engineering software and online community, this solution enables easy adaptation to changing requirements and efficient use of existing and future software services. Together with a digital marketplace for software and systematic cloud integration, PLCnext Technology is able to meet the challenges of the IoT world.

“I am pleased that we are now further intensifying our long-standing, trusting business relationship and expanding our partnership in the field of industrial control technology,” emphasizes Bruno Schnekenburger, CEO and President of Yaskawa Europe. Ulrich Leidecker, President Business Area Industrial Management and Automation (IMA) of Phoenix Contact, adds: “The openness of the PLCnext ecosystem enables a highly flexible, safe and modern automation technology. The technology partnership with Yaskawa is a milestone for the automation industry, because the more partners act in an open automation ecosystem, the more valuable it becomes for each individual participant”.

“When PLCnext Technology is combined with the proven motion control engine and robust controller hardware from Yaskawa, it will create a control platform that is open, flexible and powerful, all based on proven PLCopen toolboxes for logic control, machine control and control of delta and articulated arm robots,” according to John Payne, Senior Vice President of Motion for Yaskawa America. “This new platform will combine control for logic, motion and robotics with solutions for Industrie 4.0 applications. It will also enhance the control product offering from Yaskawa with solutions for network safety and control system security.”

For more information, visit www.yaskawa.com.