SEW P Series: Increase in Torque of up to 26%

August 17, 2020

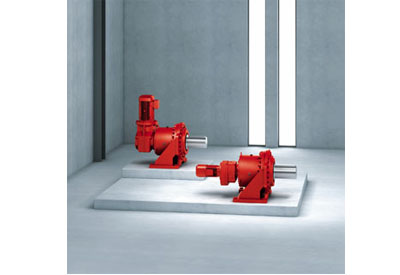

P Series

Our P series is the ideal drive solution for machines with high torques and restricted installation space. A gearmotor is directly coupled to the planetary gear unity:

Compact and cost-efficient:

- No coupling

- No intermediate flanges

- No adapter flanges

The torques of the individual sizes were increased by up to 26%:

Rated torque now ranging from 25 to 631 kNm.

Cost savings and optimization of space by choosing smaller and more compact planetary gear units.

Application for P gearmotors: Anywhere you need to move heavy weights at a low speed.

Your Advantages

- SEW delivers a complete drive whose components are optimally matched.

- Higher radial loads than comparable drive solutions.

- A planetary gearmotor is more cost-effective than a stand-alone planetary gear unit, adapter, coupling, and motor.

- A planetary gearmotor is more compact (shorter), as intermediate elements such as adapter flanges and couplings are not necessary.

- A large number of variants ensures optimum adaptation to the application.

- Finely graded gear ratios due to the high variance of the SEW gearmotor at the input end.

- Short delivery times for standard variants of 4 – 16 weeks, depending on the frame size.

- Standardized planetary gearmotors up to MN2 = 631 kNm as catalog products.

- The required data and dimension sheets for project planning are available immediately via comprehensive documentation (catalog, operating instructions).

- Quick creation of 3D models and 2D dimension sheets in the freely accessible DriveCAD tool.

- Comprehensive range of additional components available from the entire SEW modular concept.

- Comprehensive worldwide sales and service network.

- SEW as system and solution provider who supplies complete drive systems from one source.

For more information, click here.