B&R Automation: Always an Eye on Your Assets

April 27, 2020

Continuous, secure monitoring of machine data from a distance with B&R

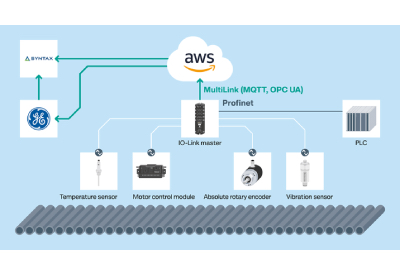

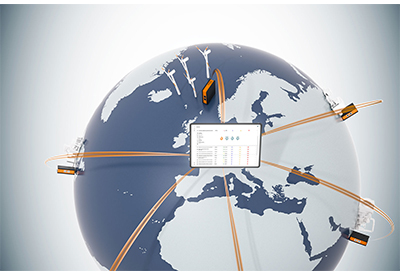

B&R enables machine builders to establish a continuous connection to plants and machinery in the field. With LogTunnel, data from machines all around the world can be archived in a central location. Any irregularities in performance can be detected early to help maintain maximum availability.

LogTunnel is feature of B&R’s Secure Remote Maintenance solution. Secure Remote Maintenance lets you check in on plants and machinery anywhere in the world from your office or on the go. Even take control of it if necessary – as though you were right there on site. Through continuous data logging, LogTunnel allows you to detect faulty components early and optimize service intervals. Setup is a simple matter of drag-and-drop and requires no special IT know-how.

Simultaneous logging and maintenance

The ongoing LogTunnel connection is not affected when a technician connects temporarily to perform remote maintenance – logging continues uninterrupted. Machine data can be stored on a central database server, in the cloud or at a data center, where it remains available for later analysis.

Secure connection

Secure Remote Maintenance functions in accordance with all the latest IT and cybersecurity guidelines. Machine builders have runtime access to machine parameters from their entire installed base. All access is logged in detail for later traceability.