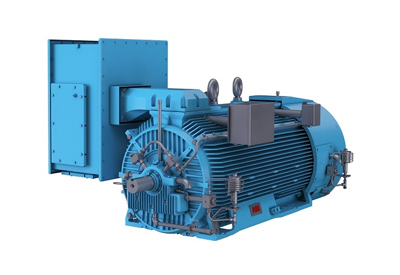

ABB’s new AXR Large AC motors offer power-dense design for hazardous locations

August 19, 2019

ABB’s AXR 5000 and 5800 motors offer more HP (horse power) per pound than conventional TEFC (totally enclosed fan cooled) motors but with a smaller frame size in some power ratings. This helps save space, up to 8 inches in overall length in some cases, which enables more compact installations on oil platforms and in refineries.

The new AXR motors also offer improved cooling, a critical factor to extend the life of the motor. An internal cooling loop circulates air inside the motor, moving heat to the frame. An external fan blows air over the frame to remove the heat.

“The new cooling configuration offers a more thermally equalized motor, eliminating hot spots that have been seen in TEFC motors,” says Charles Blankenship, Large AC Motor Product Manager, ABB. “Better cooling reduces the thermal stresses on the insulation system, which helps improve the motor’s longevity.”

As the main terminal box and auxiliary box can be mounted in several positions, installation and maintenance are easy. This also means fewer spares are needed, which saves money. The rigid frame increases stability so that the motor can meet the stringent API vibration limit specifications.

AXR motors also feature sleeve bearings that operate at cooler temperatures, last longer and are easy to maintain. These motors are available with up to an IP56 rating, for protection against contaminates and dust ingress.