Economical and Intelligent: Innovative new tire handling solutions from Bosch Rexroth

March 18, 2019

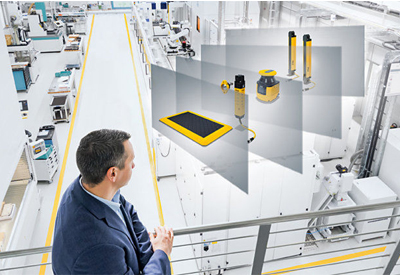

At the Tire Technology Expo 2019, Bosch Rexroth will present a new package of solutions for tire handling robots, which combines a price-optimized motion control system with an innovative operating concept.

A standard tablet is used for safe teaching and graphics-supported programming. If required, the complete package can also include a high-quality Rexroth mechanical system, an IT security solution and the IoT Gateway for industry 4.0 applications. Manufacturers and users benefit not only from low costs and extensive functions but also from maximum economy and flexibility over the entire life cycle.

The tire handling market is highly competitive and price-driven. Providers must optimize their costs while meeting strict requirements as regards robustness, accuracy and productivity. Users on the other hand want minimal delivery times, proven technologies and easy-to-use solutions, which can quickly be adapted in response to format or process changes.

Innovative new tire handling solutions from Bosch Rexroth feature:

- Economical complete package for high-quality tyre handling robots

- Innovative operation and safe teaching using a standard tablet

- Short time to market, quick adaptation during operation

- Modular complete solutions optionally available with a Rexroth mechanical system and a firewall

Safe teaching with a “bring your own” approach

Bosch Rexroth meets all of these requirements with an innovative package of solutions that combines an economical motion control system with modern web technologies and value-added functions. What makes the solutions so special is the fact that they can be operated via a standard consumer tablet and include safe teaching, visualization and programming. Bosch Rexroth has developed an adaptive bracket with a combined enabling and emergency off button for this purpose.

Modular package of solutions, optionally available with a mechanical system and a firewall

In addition to a motion control system with comprehensive software functions, the basic package also includes a safety control system for connecting the tablet bracket as well as compact servo motors and drives for moving the kinematic system. As an option, Bosch Rexroth also supplies the complete mechanical system for the handling system including a grabber and linear modules with a belt or ball-screw drive. An additional option for the package of solutions: the IoT Gateway which makes it easy to collect data for continual process improvement during operation, e.g. through Condition Monitoring and predictive maintenance. If necessary, communication standards such as OPC UA allow easier integration into customer-specific IoT systems. The package is complemented by the secure router whose firewall monitors data traffic between the tablet, control system and company network while preventing unauthorized access in all directions.

Rapid commissioning, greater flexibility during operation

The drives can be put into operation without parameterization. This speeds up the time-to-market. Once the servomotor is connected to the drive, it automatically reads out the feedback memory containing the kinematic parameters. The handling system processes can be defined without programming knowledge with the help of the visual code editor Google Blockly. The user’s tablet which visualizes all steps in the web browser on the basis of HTML5 serves as the HMI – just as it does during safe teaching. This avoids additional hardware costs and training outlay while eliminating sources of error both during the initial set-up and in the event of subsequent changes to processes and formats.

Software functions for greater productivity and quality

With numerous software functions, the motion control increases availability and product quality. For example, the “Active Vibration Absorption” function initiates exact counter-movements for the linear module in order to avoid unwanted vibrations or to move delicate products carefully. It does this either through an open-loop process or in combination with a sensor. As a result, the gripper achieves maximum accuracy when loading and unloading and the operating life of the mechanics is extended.