Bosch Rexroth, driving performance and value-added functions for mobile working machines

February 13, 2019

The BODAS-drive eDA is a future-compatible and scalable control solution for hydrostatic travel drives. It is available either as a completely pre-programmed or an open, extensible system.

With a specially-matched package of software and components, Rexroth offers an electronic variant of its hydraulic DA controls, which are characterized by their driving comfort and reliability. The eDA is particularly suitable for wheeled loaders, telescopic handlers and fork lift trucks, but also for many other applications that previously used conventional DA controls. As a basic solution, with a fully electronified A4VG drive pump and A6VM hydraulic motor, the electrohydraulic solution opens up new machine concepts and target markets for manufacturers.

The statutory limits for exhaust emissions are becoming more restrictive, fuel consumption costs are rising, and additional functions are increasingly important. To cope with these factors, the electronic control of hydrostatic drives for mobile working machines offers decisive advantages. With eDA, Rexroth offers a comprehensive package that includes the electronic, speed-dependent control of hydrostatic gearboxes. For more complex drive architectures with transmission management, the proven control solution BODAS-drive DRC remains essential. As an alternative to strictly hydraulic DA controls, BODAS-drive eDA is an appealing electronified solution for simpler drive architectures.

The BODAS-drive eDA is a future-compatible and scalable control solution. It is available either as a completely pre-programmed or as an open, extensible system. A graphic user interface, combined with practical user instructions, makes a guided commissioning possible. The parameterization of the pre-programmed functions is based on the established physical parameters of the machine. The number of dynamic parameters is reduced to a minimum, and the software structure minimizes the interdependencies. The entire system is based on a structured, step-by-step optimization. Customers can easily integrate specific desired features, such as operating elements or functions regarding the travel drive, working hydraulics, or the vehicle’s electrical system, or jointly develop them in cooperation with Rexroth.

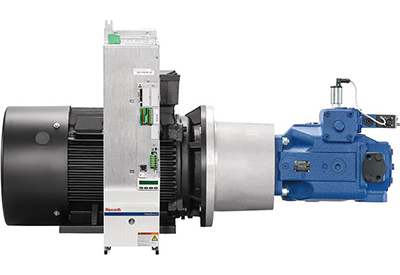

The A4VG series 35 new pump generation is perfectly matched to the BODAS-drive eDA software. Thanks to the integrated sensor technology, it is particularly suitable for use in electronified travel drives. The design has been optimized based on load collectives for travel drives. The result is a compact structural design and high power density, with a nominal pressure of 400 bar and a maximum pressure of 530 bar.

In combination with the proven A6VM variable displacement motor, it allows for an optimal system design. As the series 71 from Bosch Rexroth, it was optimized for efficiency and equipped with a specially matched electronic interface and integrated speed sensor.

The SRC-eDA electronic control unit of the new series 40 serves as the central interface of the software and all components. It can be freely positioned in the vehicle and it hosts the drive- and value-added-functions. Furthermore, it realizes the safety functions according to the EN ISO 13849 standard based on a monitoring concept. This facilitates verification processes and enables the efficient design of safe machines.

The specially-matched eDA package supports the digital conversion of hydrostatic drives. Features such as ECO drive, inching, a variable creeping mode, different driving modes or adjustable reversing behaviour make it possible to construct innovative and future-compatible working machines even on the basis of simple drivetrain architectures. At bauma 2019, interested machine manufacturers can find out more about the driving performance and functions of the eDA package for themselves.