EPLAN: A new design for EPLAN Electric P8

January 10, 2019

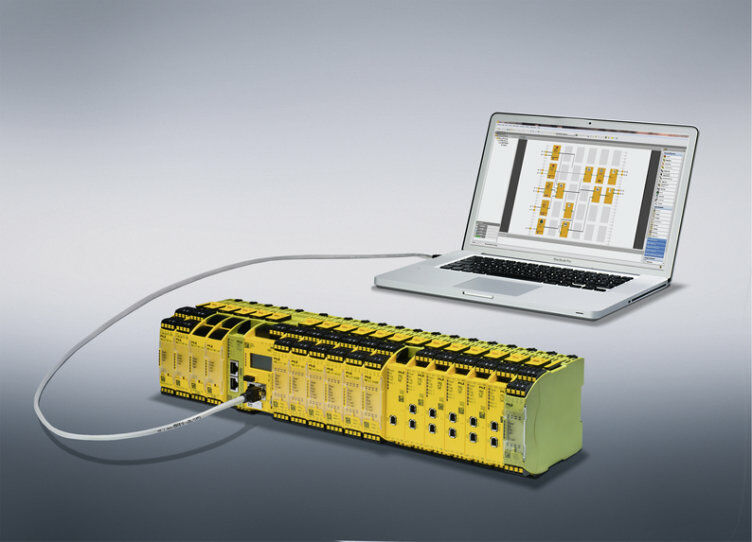

Much has been said about EPLAN Platform, Version 2.8. Now, just a few days before the rollout, the focus is on EPLAN Electric P8. Users can look forward to enhancements in the areas of configuration, bus data and round-trip engineering with Siemens TIA Portal. EPLAN Electric P8, the established CAE solution, further surprises by introducing a completely new user interface and an integrated user portal.

A new graphical user interface, increased ergonomics and enhanced macro technology are all hallmarks of the new EPLAN Platform, Version 2.8. Yet that’s not everything: a new portal directly integrated into the software solution welcomes users right upon start-up moving forward. Offering comprehensive information, it includes tips and tricks that make users’ everyday work even easier, not to mention news and innovations from the EPLAN product portfolio, tutorials, details about training opportunities and much, much more.

Expanded data exchange with TIA Portal

Furthermore, the individual systems such as EPLAN Electric P8 are showcasing a variety of new features. The first step includes improvements in the bidirectional interaction between EPLAN and TIA Portal. In Nuremburg, users can discover how the AutomationML format even more effectively supports round-trip engineering, which again optimises the configuration of PLC data.

In the “Edit terminal strip” dialogue, users will soon be 7able to assign several alignable accessories at the same time. All of the devices selected in the appropriate context menu are then assigned to the marked terminal strip. This saves time in engineering.

Transferring configuration projects

With a new menu item, users can now transfer configuration projects – for instance the data for a PLC box – to the corresponding bus ports, eliminating the time-consuming task of manually inputting the data for each individual port. Potentially existing bus port entries are hereby updated. If an individual bus port is assigned to another configuration project, this value can then be manually changed, all of which provides more flexibility in engineering.

Bus data now available for all representation types

EPLAN Electric P8 users could previously only input bus data for single-line network/bus wiring cable connections. What’s newly available to users in the properties dialogue for bus connections is the “Bus data” tab for all representation types. This allows bus data to be input into the schematic and displayed without a single-line representation being specified. Yet another practical advantage: bus data are no longer deleted when changing the representation type. This provides more freedom within a project.