IAMD 2019: A world of solutions for smart factories

October 18, 2018

Smart sensors, intelligent drives, modular production, automated logistics systems and holistic solutions for intelligent manufacturing – HANNOVER MESSE has it all. From 1 to 5 April, the world’s leading trade fair for industrial technology will open its gates under the motto “Integrated Industry – Industrial Intelligence”. The motto reflects the organizer’s desire to show how the close integration of automation, power transmission and fluid power and software and IT can supercharge industrial production. At HANNOVER MESSE 2019, this pivotal confluence of technologies will be clustered at Integrated Automation, Motion & Drives (IAMD) – a mega-show spanning 14 exhibition halls.

Hannover. In 2019, the integration, digitization and interconnection of industrial technologies will transform the world’s manufacturing industries more than ever before. In recognition of this, the IAMD show will feature the full range of products and solutions for the factory of the future, including factory and process automation systems, industrial IT, robotics, smart drives, and intelligent hydraulics and pneumatics systems. All of the exhibits will share one unifying theme: “Industrial Intelligence” , which is also the official lead theme for HANNOVER MESSE 2019. Artificial intelligence and machine learning are helping to eliminate production downtime, boost efficiency and ensure the seamless integration and operation of all the different parts that make up smart factories.

The over 200,000 trade visitors attending the upcoming HANNOVER MESSE will come from a diverse range of user industries. But most will come to the fair with the same clear objective in mind: to find the right state-of-the-art smart automation solutions for their manufacturing operations. For the companies they represent, digitization is the key to keeping their competitive edge.

“Automation solutions for the digitization and smart integration of industrial technologies will be the focus of the upcoming IAMDshow,” said Arno Reich, Global Director IAMD for HANNOVER MESSE. “IAMD will also showcase the best power transmission and fluid power technologies the world has to offer, as well as serving as a central forum for debate on the latest market and technology trends.”

While there are still over six months to go until the gates open on the next HANNOVER MESSE, a large number of market leaders – among them Siemens, ABB, Festo, Bosch Rexroth, Schneider Electric, Phoenix Contact and Beckhoff – have already registered display space. Confirmed exhibitors of intelligent power transmission and fluid power technology solutions include SEW EURODRIVE, Schaeffler, Continental, Aventics, Hydac, KTR, Parker Hannifin, Trelleborg and ZF Friedrichshafen.

All the market leaders in the robotics industry will also be represented at the show, including FANUC, KUKA, Yaskawa, Kawasaki, Universal Robots, HIWIN and Mitsubishi. HANNOVER MESSE’s robotics showcase has been growing steadily for many years and reliably delivers an accurate snapshot of the current state of the art. A key trend in the industry has been the emergence of cobots (collaborative robots), which, rather than replacing humans, are designed to work alongside them. At the upcoming HANNOVER MESSE, the most innovative robotics solutions will once again be celebrated as part of the ROBOTICS AWARD .

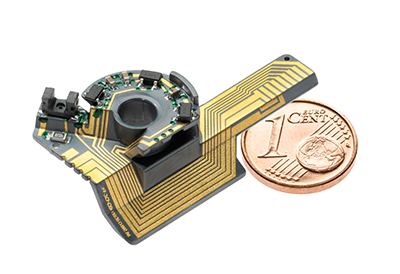

Sensor systems are a key enabling technology for fully integrated, interconnected and intelligent operations across a wide range of different industries, including the energy industry, the mechanical engineering industry and the eMobility sector. The fact that sensor technology has become something of a unifying theme throughout HANNOVER MESSE will be borne out by leading market players, such as ifm electronic, SICK, Pepperl + Fuchs, Hans Turck and Balluff.

Apart from the exhibits, trade visitors can look forward to a comprehensive supporting program of forums and special presentations, including the HANNOVER MESSE PUMP PLAZA ; the Wireless, M2M & IoT display; the Application Park showcase for robot manufacturers, systems integrators and image processing specialists; and a new SME Pavilion where small and mid-sized companies will present their Industry 4.0 solutions. Among HANNOVER MESSE’s many platforms for learning, knowledge sharing and lively debate on the latest trends and developments will be the new Motion & Drives Forum and the well-establishedAutomation and Industry 4.0 forums within the IAMD show.