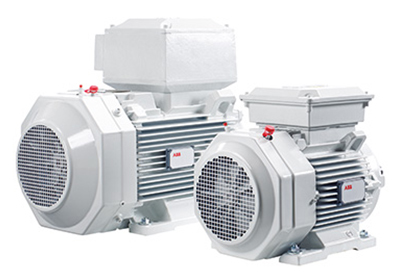

ABB Ability™ Smart Sensor for Motors

July 3, 2018

The ABB Ability™ Smart Sensor converts traditional motors into smart, wirelessly connected devices. It is attached to the frame of low voltage induction motors. No wiring or machining is needed. Using algorithms, based on ABB’s decades of motor expertise, the ABB Ability™ Smart Sensor relays information about the motor’s operation and health via a Bluetooth-gateway or smartphone to a secure server.”

The ABB Ability™ Smart Sensor picks up data on vibration, temperature and other parameters that can be used to gain meaningful information on the condition and performance of the motor, enabling users to identify inefficiencies within their system and to reduce risks related to operation and maintenance. Maintenance can now be planned according to actual needs rather than based on generic schedules. This extends equipment lifetime, cuts maintenance costs and reduces or prevents unplanned downtime due to breakdowns. ABB Ability™ Smart Sensor for motors can help you to

– Identify inefficiencies within the system

– Uncover potential for energy savings

– Reduce risks related to operation and maintenance

– Prevent unexpected breakdowns

– Extend equipment lifetime

Product highlights

– Simple to install and use

– No wiring or machining is needed

– Data transfer via built-in wireless Bluetooth® Low Energy

– Data communications use industry standard encryption protocols

– All data is securely stored in the cloud

For more information HERE